Maximize material usage and quote smarter — with one click.

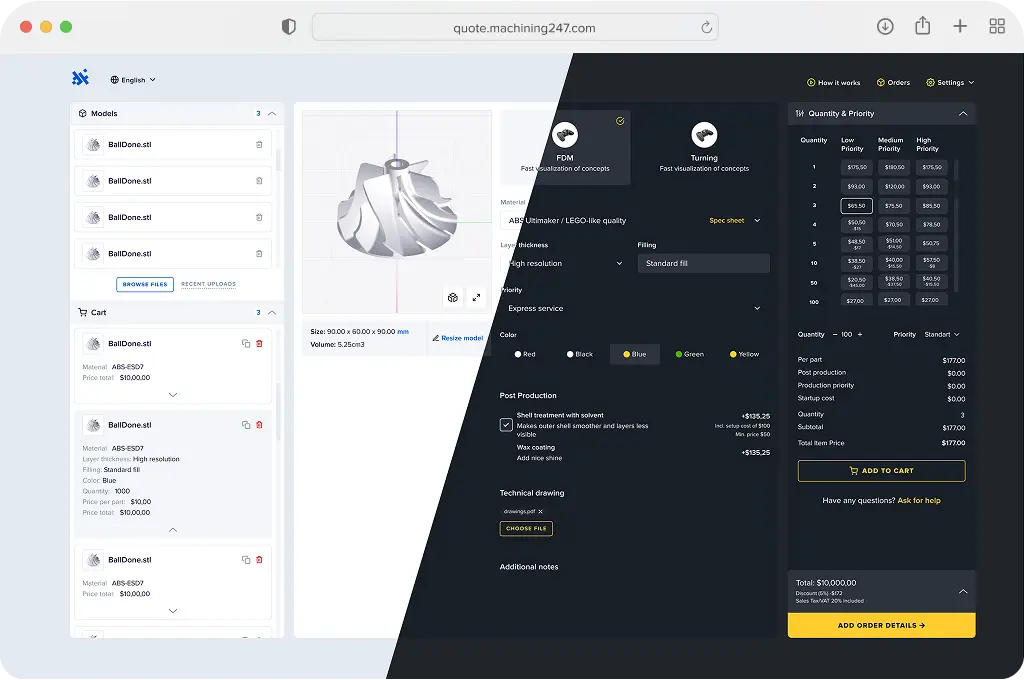

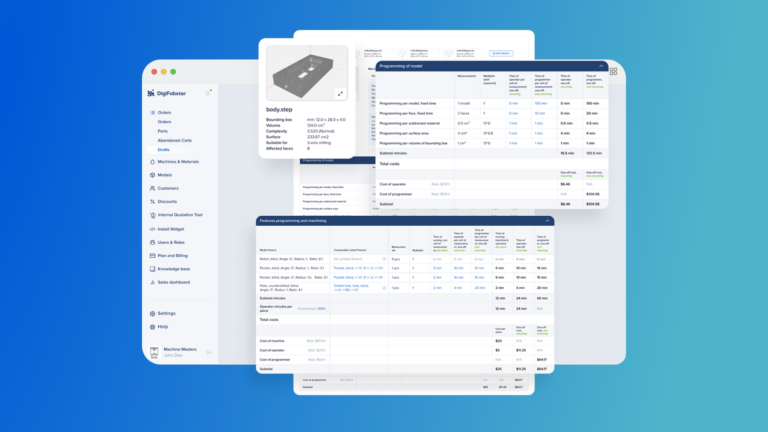

DigiFabster’s Nesting feature for laser cutting and sheet metal fabrication analyzes your part geometry and orientation to fit as many parts as possible onto a single sheet. This helps optimize raw material usage, reduce scrap, and improve production efficiency — especially for high-volume or multi-part jobs.

It’s a powerful tool for fabrication shops, metal parts manufacturers, and any machine shop quoting sheet metal work or laser cutting services.

🔧 What It Does

With Nesting, you can:

- Analyze all parts in an order and automatically nest them for optimal layout

- Fit multiple part copies onto a single sheet of material based on:

- Part geometry

- Orientation

- Sheet size

- Reduce waste and calculate material cost more accurately

- Use the nested file output to inform more efficient cost estimation and job planning

Nested layouts can be generated and applied with just one click — giving you better insights into the true material and time cost of an order.

🏭 Problems This Solves

Problem: Material usage is hard to estimate accurately

✅ Solution: Nesting provides a realistic layout so you can see how many parts fit on each sheet — improving your quoting software accuracy.

Problem: Manual nesting wastes time and leaves room for error

✅ Solution: Automate the process and apply nesting in seconds, helping your estimating software and workflow automation tools work smarter.

Problem: Material waste increases job cost unnecessarily

✅ Solution: Nesting reduces scrap and supports cost reduction strategies in metal fabrication and sheet metal work.

🚀 How It Works

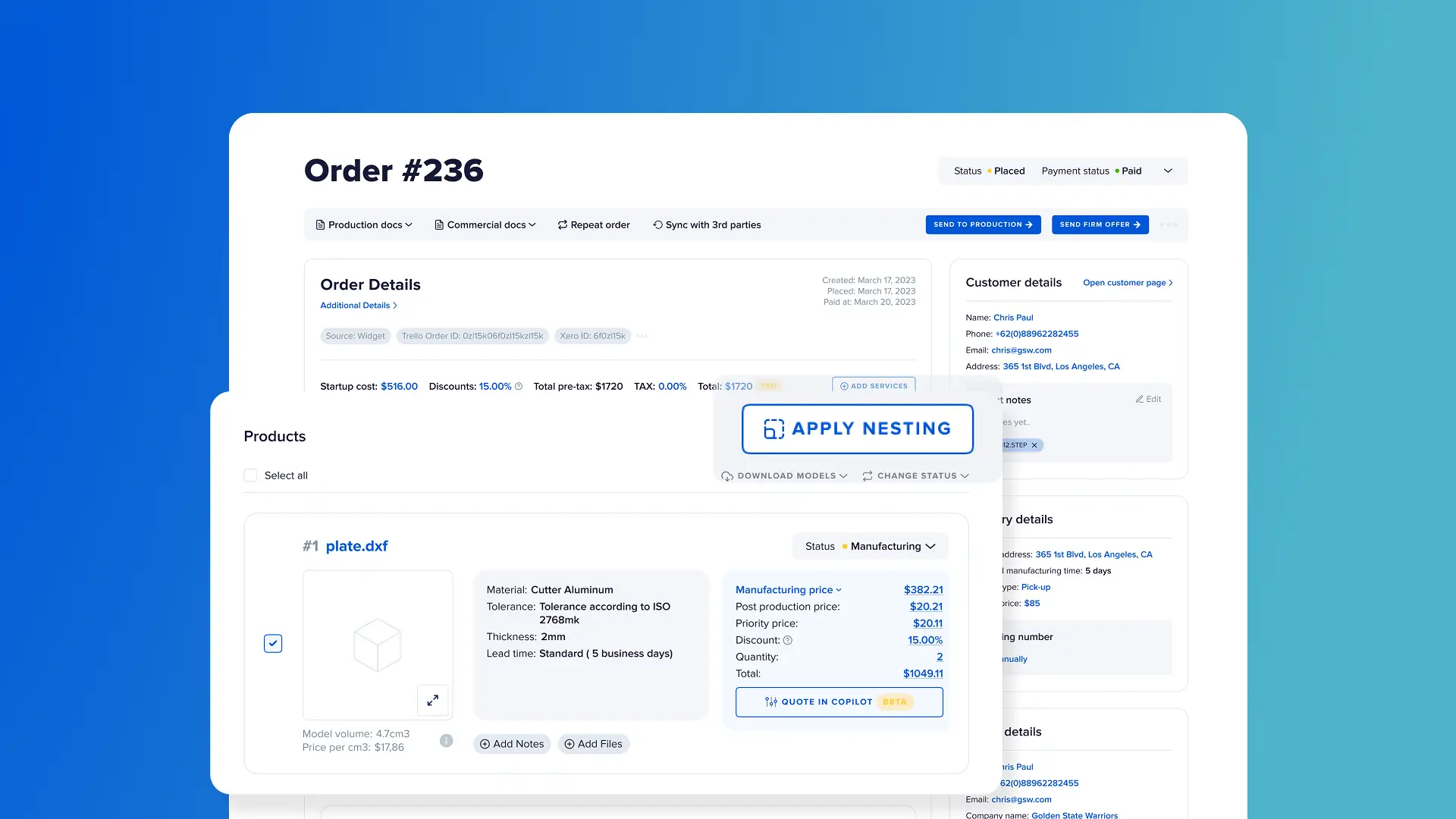

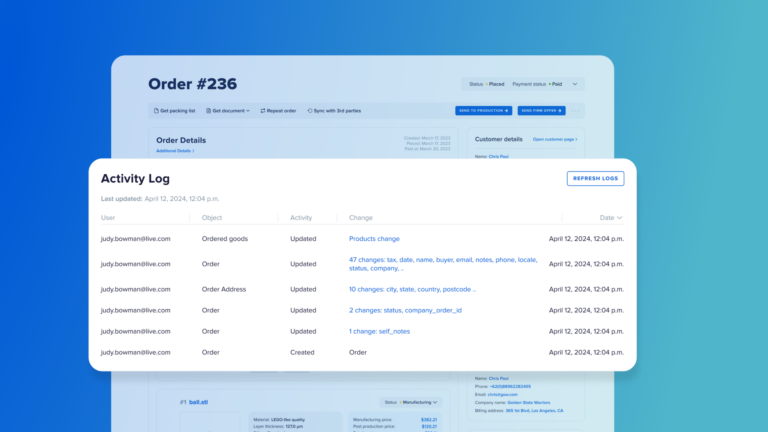

- Go to the Order Details page

- Click “Apply Nesting”

- The system analyzes all laser-cut or sheet metal parts in the order

- A nested file is created and saved with the order for download or reference

You can then use this file for quicker quoting, material purchasing, or production planning.

💡 Pro Tip

Use nesting early in the quoting phase to improve the accuracy of large or multi-part jobs. This is especially helpful when dealing with high-volume aluminum fabrication, stainless steel parts, or custom sheet metal components — where even small optimizations can save big on cost and material.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.