Edit, reconfigure, and track every part in the order — down to the smallest detail.

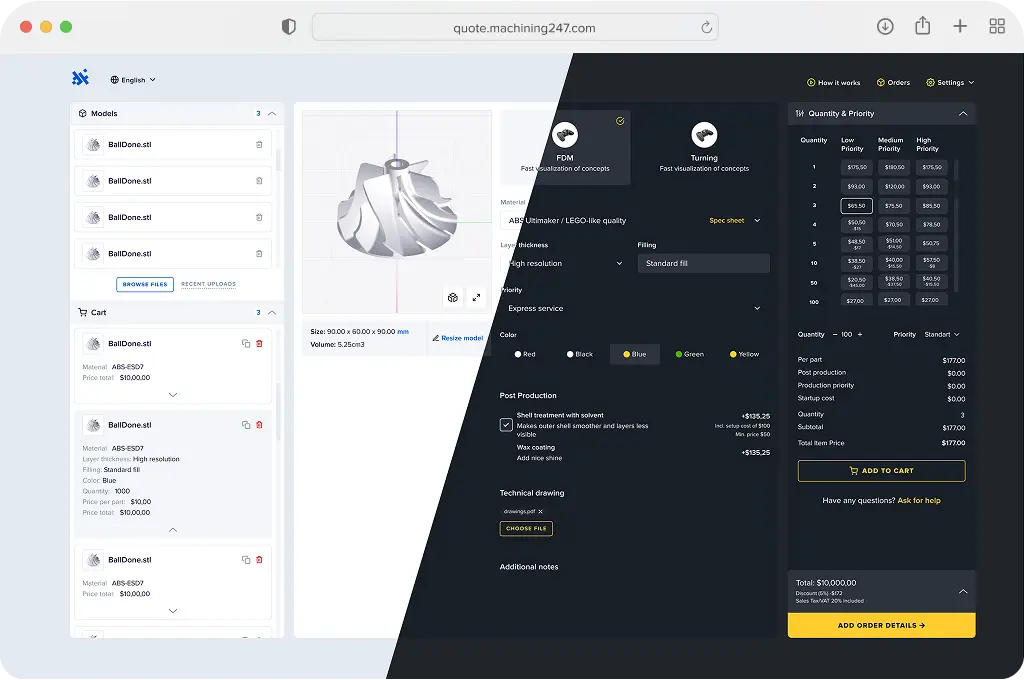

DigiFabster’s Line Items Review & Editing feature gives you full control over every part inside an order. From materials and technologies to individual discounts and cost breakdowns, this tool lets you fine-tune each item, streamline communication, and improve quoting precision across your manufacturing operations.

Built for custom machine shops, metal fabrication companies, 3D printing providers, and any on-demand manufacturer working with configurable or multi-part jobs.

🔧 What It Does

With this feature, you can:

- Open any order and edit all line items individually or in bulk

- Change or update:

- Material

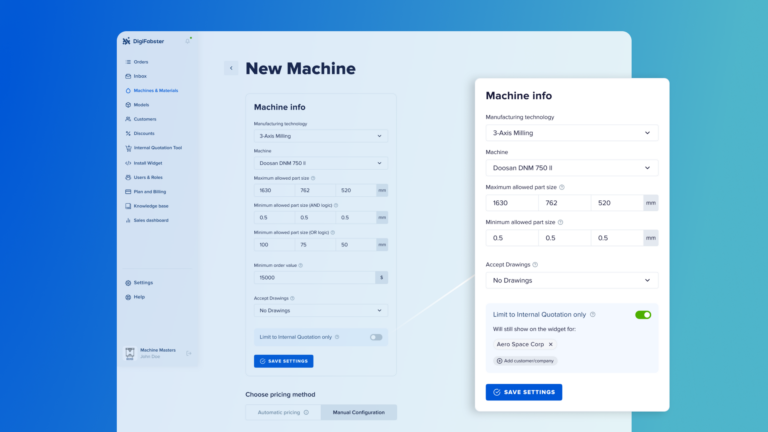

- Manufacturing technology (CNC machining, laser cutting, 3D printing, etc.)

- Post-processing options

- Tolerance settings

- Priority (lead time)

- Manufacturing status (single or multiple line items)

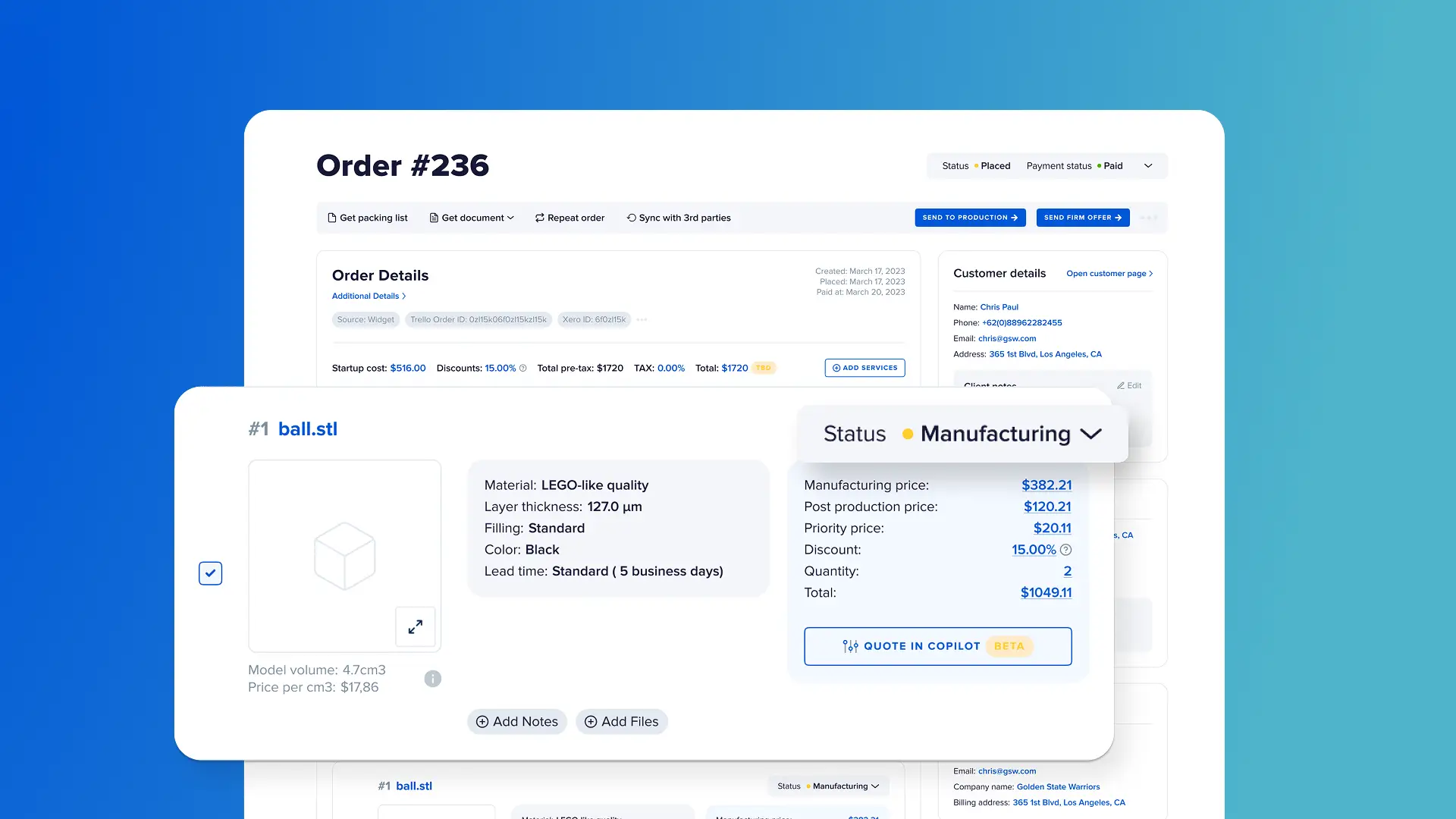

- Recalculate pricing using Quoting Copilot:

- Adjust time-based parameters like machine time, setup time, operator time

- Apply the result only to this part or save it globally for this machine/material combo

- View and manage:

- Manufacturing price breakdown (recurring + non-recurring costs)

- Line item model details like volume, dimensions, bounding box, surface area

- Discounts applied per line item

- Internal notes and internal attachments

- 3D model viewer for in-browser inspection

- Downloadable models’ files (CAD, STEP, STL, etc.)

This functionality supports precision in your cost estimation software, improves job accuracy, and adds flexibility in your CPQ or MES workflow.

🏭 Problems This Solves

Problem: You can’t easily adjust parts once the order is placed

✅ Solution: Reconfigure every element — from material to tolerance — without restarting the order.

Problem: Lack of pricing transparency or control on part level

✅ Solution: View detailed breakdowns and apply manual overrides, discounts, or time-based pricing logic per part.

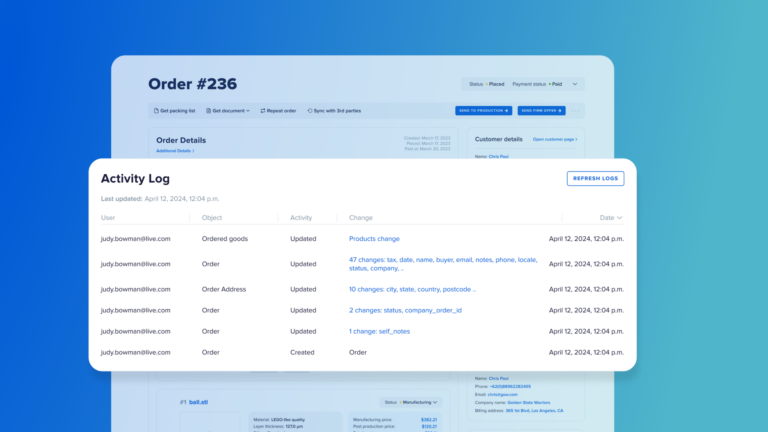

Problem: Hard to update manufacturing statuses for complex orders

✅ Solution: Change statuses for one or multiple line items at once to stay in sync with production stages.

🚀 How It Works

- Open any order

- Scroll to the line items section

- Click into any line item to:

- Edit specs, pricing, and post-processing

- Launch Quoting Copilot for advanced cost configuration

- View or update model data, status, or discounts

- Use the 3D viewer to inspect geometry

- Download the file or apply saved pricing logic as needed

- Add internal notes or customer-visible files

💡 Pro Tip

Use this feature to fine-tune high-complexity or high-value parts — especially in precision machining, sheet metal, multijet fusion, or prototype manufacturing — where small adjustments in setup time or post-processing can significantly affect margins.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.