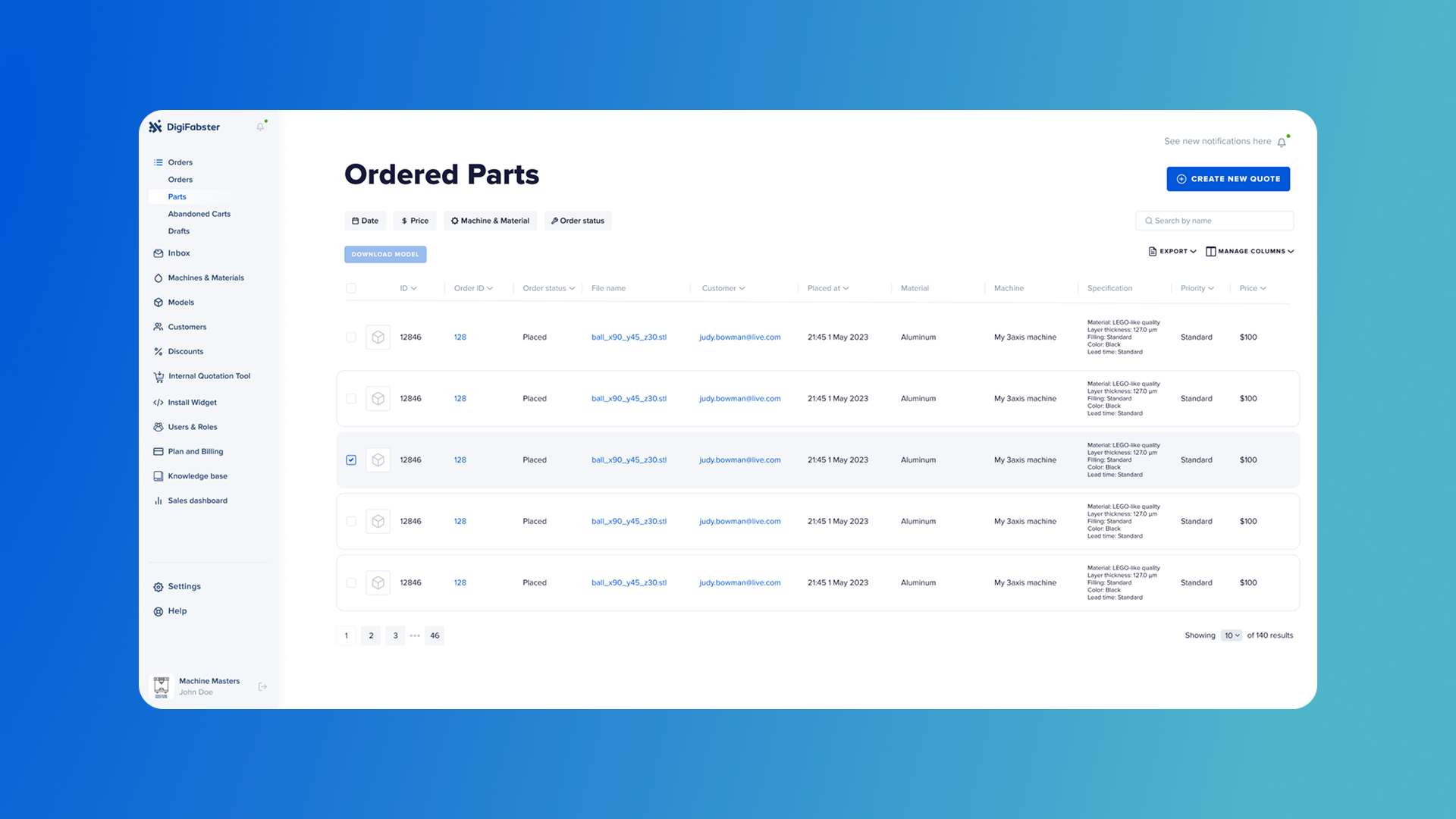

Track, manage, and edit every part across all orders — in one place.

DigiFabster’s Parts View (Line Item View) gives you a dedicated interface to review and manage all individual parts ordered through your platform. With powerful filtering, sorting, and bulk editing tools, it’s the perfect companion for production teams that need to focus on part-level execution, not just order-level tracking.

Ideal for fabrication shops, custom machine shops, 3D printing services, and other on-demand manufacturers dealing with multi-line orders, high part volume, or shared production resources.

🔧 What It Does

From the Parts View, you can:

- See all parts across all orders in a structured table view

- Filter and sort by:

- Price

- Date

- Material

- Assigned machine

- Production priority

- Search by model ID or part name

- Click the Order ID in any row to jump directly to the parent order

- Perform bulk edits to update line item manufacturing status

- Export parts list as a CSV file for reporting or scheduling purposes

This view connects seamlessly with your order management, job tracking, and production planning workflow.

🏭 Problems This Solves

Problem: It’s hard to track individual parts within large or multi-line orders

✅ Solution: See every part from every order in one place — filterable, sortable, and searchable.

Problem: Updating production status for multiple parts takes too long

✅ Solution: Use bulk editing to move several line items forward at once — ideal for grouped manufacturing runs.

Problem: Reporting on parts or materials is too manual

✅ Solution: Export selected parts by material, machine, or priority in just a few clicks.

🚀 How It Works

- Go to Orders → Parts View

- Apply filters by date, material, machine, status, or model ID

- Click any Order ID to view the full order

- Select one or more line items to edit manufacturing status

- Export data to CSV

💡 Pro Tip

Use Parts View during daily production meetings to prioritize jobs across machines and materials. It’s especially powerful for sheet metal work, CNC machining, or laser cutting operations where parts from different orders are batched together for efficiency.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.