Not all manufacturing shops grow — but the ones that do, often have surprisingly similar habits, systems, and mindsets. Whether it’s a custom machine shop quoting five parts a day or a contract manufacturer processing hundreds of files per week, the fastest-growing teams share a common thread: they build scalable infrastructure before growth forces it.

Here’s what those shops do differently — and how Digifabster helps them do it even better.

1. They Don’t Quote in Spreadsheets Anymore

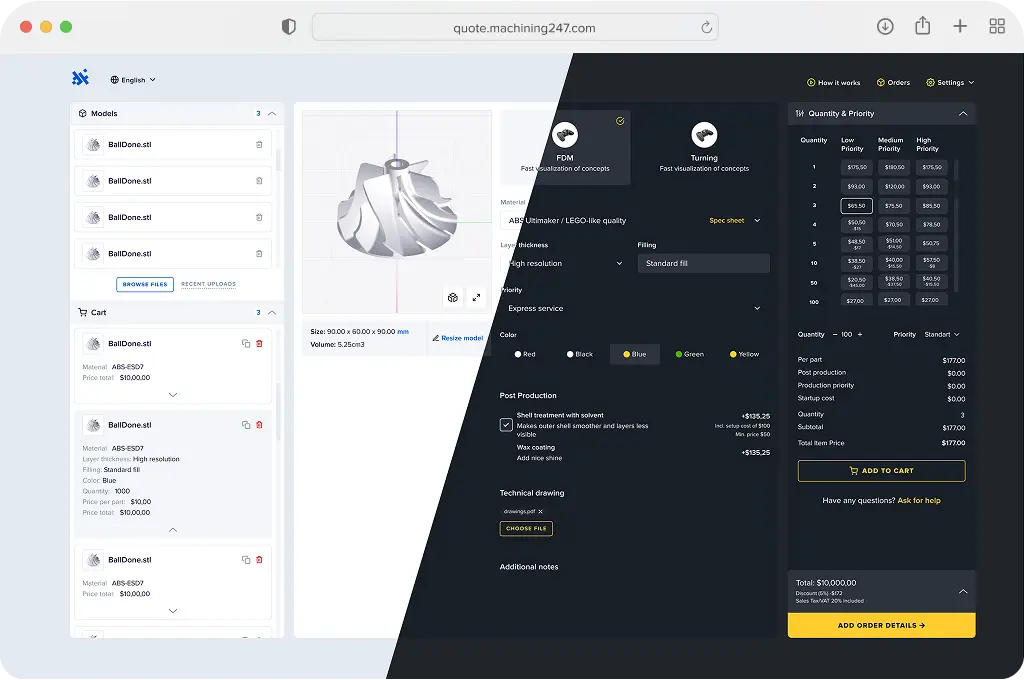

Growing shops know that manual quoting in Excel doesn’t scale. One missed formula, one forgotten markup, and the profit is gone. That’s why they invest in tools like quote software and cost estimation platforms that:

- Analyze CAD files, STEPs, STLs, and DXFs automatically

- Apply consistent pricing logic across the board

- Handle both simple prototypes and complex assemblies

With Digifabster’s instant quote software, your quoting process becomes a growth engine — not a bottleneck.

2. They Let Customers Self-Serve

The old way: back-and-forth emails, scattered RFQs, manual uploads.

The new way: customers upload files, configure materials and quantities, and get instant pricing.

By enabling an online quote system on your website, you eliminate friction and capture more business — even after hours. Growing shops understand that modern buyers expect Amazon-style ease, even when ordering sheet metal parts, CNC components, or 3D printed prototypes.

Digifabster’s widget makes your website a 24/7 online manufacturing platform.

3. They Automate Repetitive Tasks

Instead of wasting time copying files, sending invoices, and managing orders by hand, scaling teams:

- Use workflow automation to handle repetitive tasks

- Automatically generate invoices and accept online payments

- Sync data with their CRM or ERP systems

Digifabster helps growing shops remove themselves from day-to-day admin and refocus on sales, production, and quality.

4. They Quote Faster — and Win More Jobs

Speed matters. Customers often send RFQs to multiple vendors — the first to respond wins. Shops that quote in hours (or seconds) consistently outperform those stuck waiting on an estimator.

With Digifabster’s cost calculator and customizable pricing rules, your team can deliver quotes instantly — while still retaining full control and manual review options when needed.

5. They Track and Learn From Every Quote

Growth requires visibility. High-performing shops track quote conversion rates, average margins, and customer behavior. Instead of wondering what’s working, they know.

Digifabster’s dashboard shows:

- Quote volume and value

- Conversion trends

- Technology and material usage patterns

- Top customers and most-requested services

Data-driven decisions make scaling not just possible, but predictable.

6. They Invest in the Right Tools — Before They’re Drowning

Successful shops don’t wait until they’re overwhelmed. They adopt the right estimating software, order management tools, and automated quoting systems before the chaos starts. That’s how they stay ahead — and sane.

Digifabster was built for exactly that kind of team.

Final Thoughts: Ready to Join Them?

Whether you’re quoting parts for laser cutting, multi-axis milling, 3D printing, or metal bending, the pattern is clear: the fastest-growing shops build systems that scale with them.

Digifabster helps you move faster, work smarter, and stay focused on what actually drives your business.

Proven Impact, Worldwide

Manufacturers around the world are scaling with Digifabster. From CNC shops in the U.S. to fabricators in Europe, our customers cut quoting time, grow revenue, and handle more orders — without adding overhead.

👉 See real-world results in our case studies.

Ready for the switch?

Learn more about Digifabster’s instant quoting, order management, invoicing, and payment solution here.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.