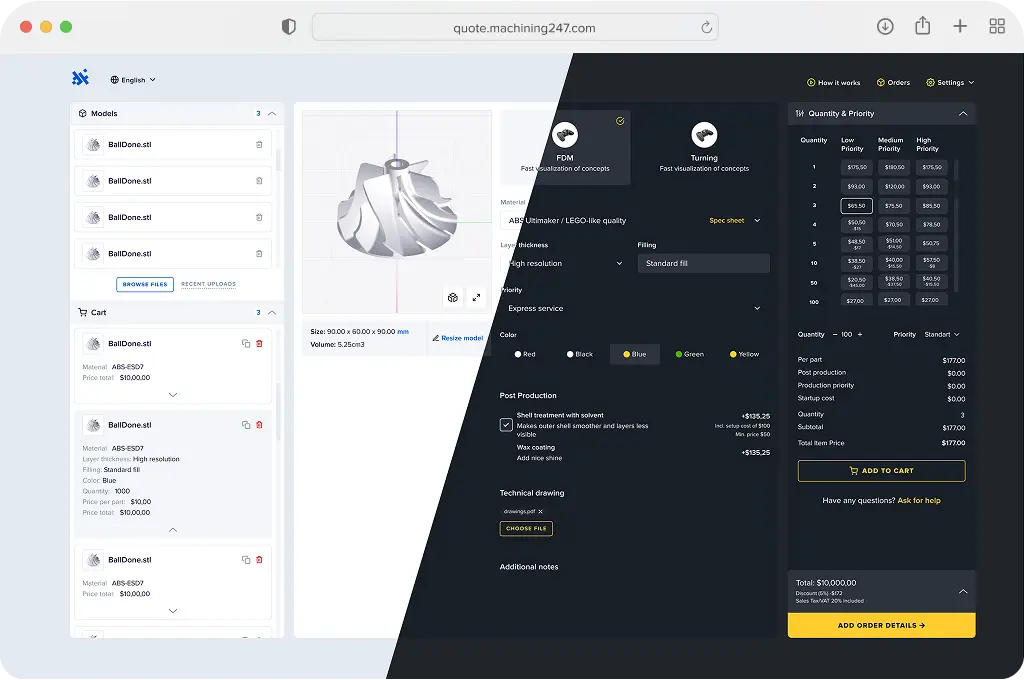

Choose the pricing model that works best for your workflow — or combine both for ultimate accuracy.

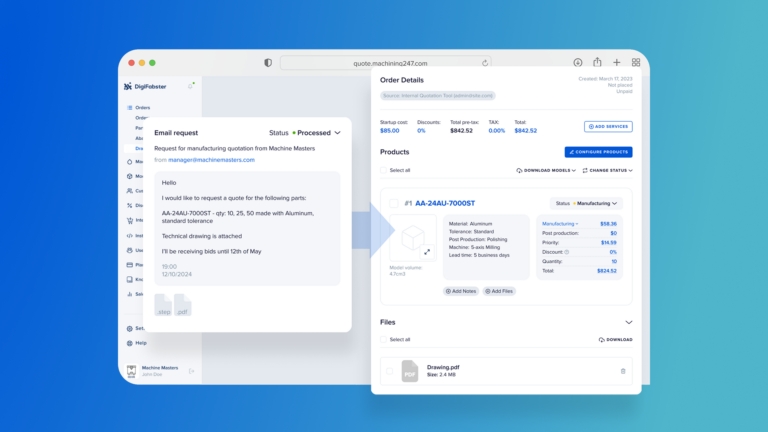

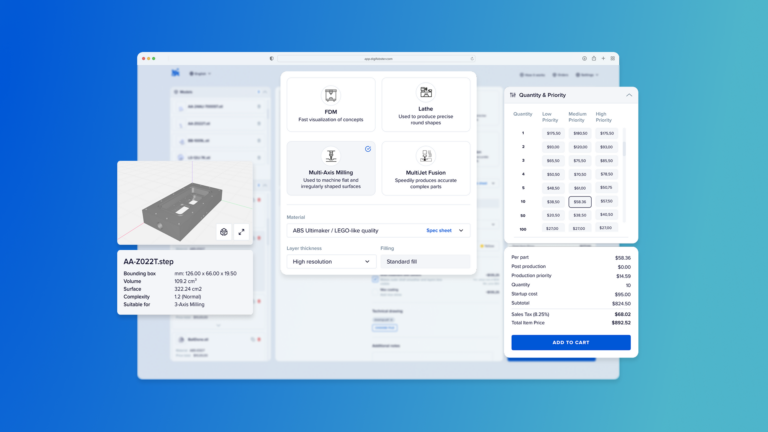

DigiFabster gives you full control over how you price your parts. Whether you’re quoting for CNC machining, metal fabrication, 3D printing, or sheet metal work, you can configure your system to use Time-Based Pricing, Cost-Based Pricing, or a blend of both — all driven by part geometry and feature recognition.

This is precision quoting built for real-world job shops, fabrication companies, and on-demand manufacturers.

🔧 What It Does

DigiFabster allows you to automate pricing using two powerful models:

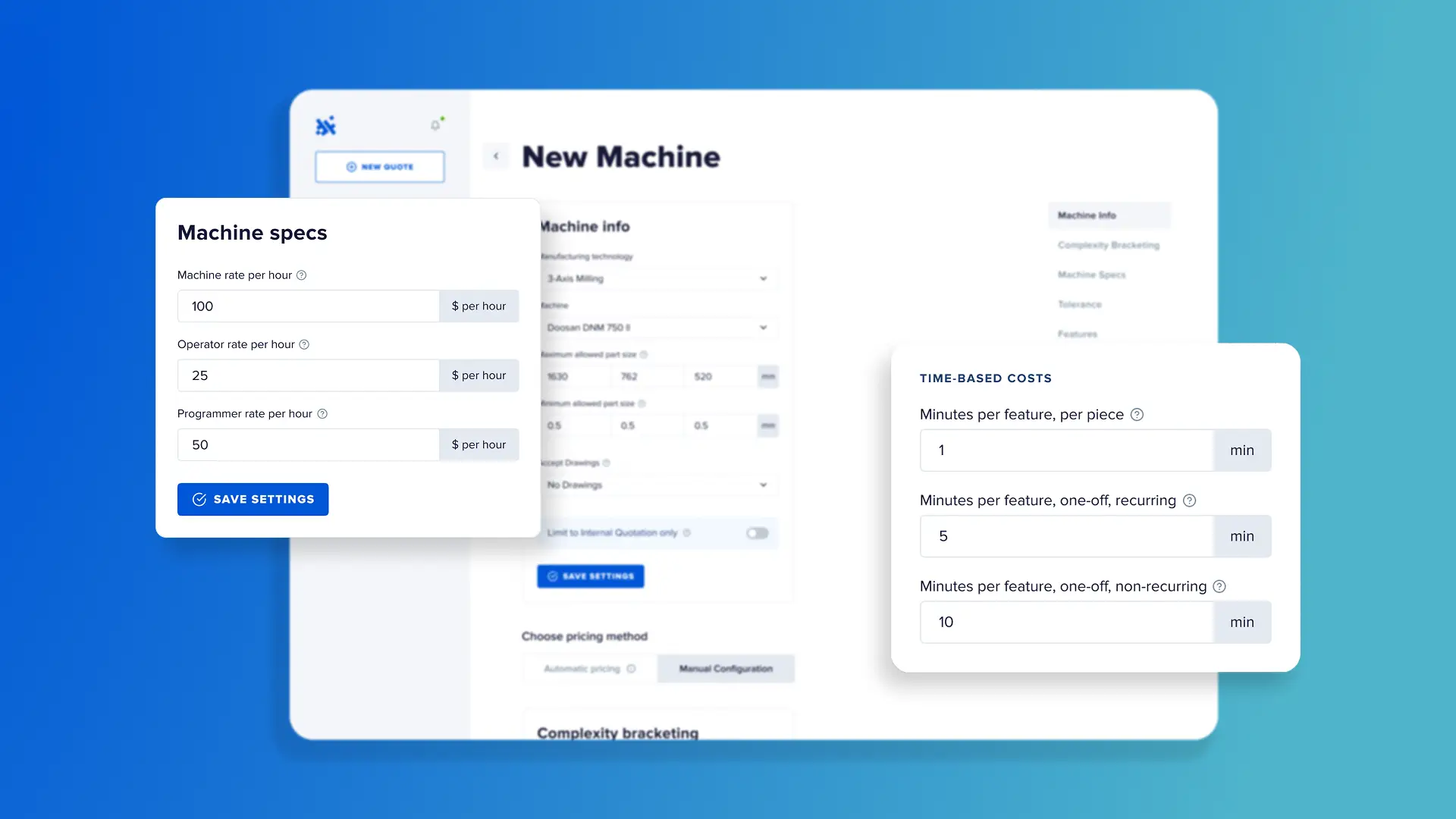

- Time-Based Pricing

– Calculates cost based on machine runtime, operator time, and programming hours

– Ideal for machine shops quoting CNC, milling, laser cutting, multi-axis, or metal bending operations - Cost-Based Pricing

– Calculates per-part pricing using fixed or variable values for:- Material

- Setup

- Post-processing

- Programming

- Tooling – Ideal for high-volume, standardized parts or when using bulk pricing logic

Both models use data from:

- CAD file analysis

- Feature recognition (e.g., holes, pockets, threads, etc.)

- Geometry detection (volume, surface area, complexity, etc.)

You can mix and match both pricing methods, applying different models per process, material, or customer type — perfect for hybrid workflows in modern manufacturing operations.

🏭 Problems This Solves

Problem: Flat-rate pricing doesn’t reflect real production time or effort

✅ Solution: Use Time-Based Pricing to capture real machine time, operator involvement, and programming effort — leading to smarter job costing and better margins.

Problem: High-volume jobs need lean, standardized quotes

✅ Solution: Use Cost-Based Pricing for faster, template-driven quotes, great for fabrication services, metal shops, and contract manufacturers.

Problem: One pricing model doesn’t fit every job

✅ Solution: Combine both to handle everything from custom prototypes to repeat production runs.

🚀 How It Works

You can specify Time-Based and/or Cost-Based costs for your machines/materials using two options.

- Machines and Materials settings

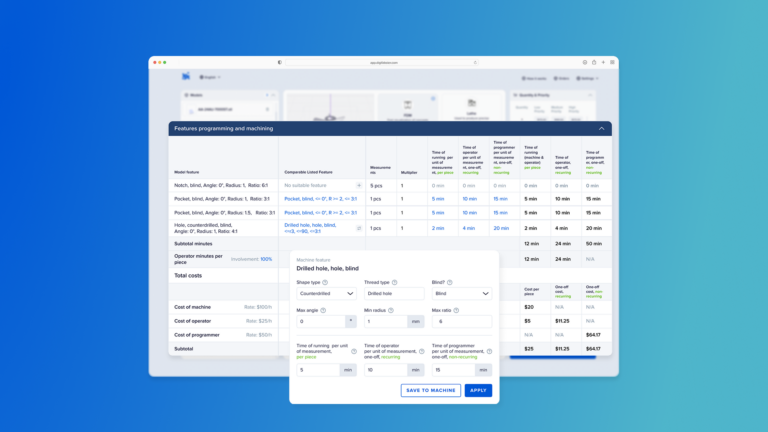

– Go to Machines and Materials settings to set machine, operator, and programming time or costs per for material, setup, and programming costs. - Configure your rates using the Quoting Copilot

– You can set rates/costs with the Quoting Copilot that allows you to quickly how automatic pricing works for any part, while having a full control over each parameter. Read more about the Quoting Copilot here.

💡 Pro Tip

Time-Based Pricing is ideal for complex parts with multiple features and tight tolerances. Cost-Based works well for quick-turn sheet metal jobs or standard parts with low variation. Use both in tandem for a powerful, flexible CPQ workflow that adapts to your business.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.