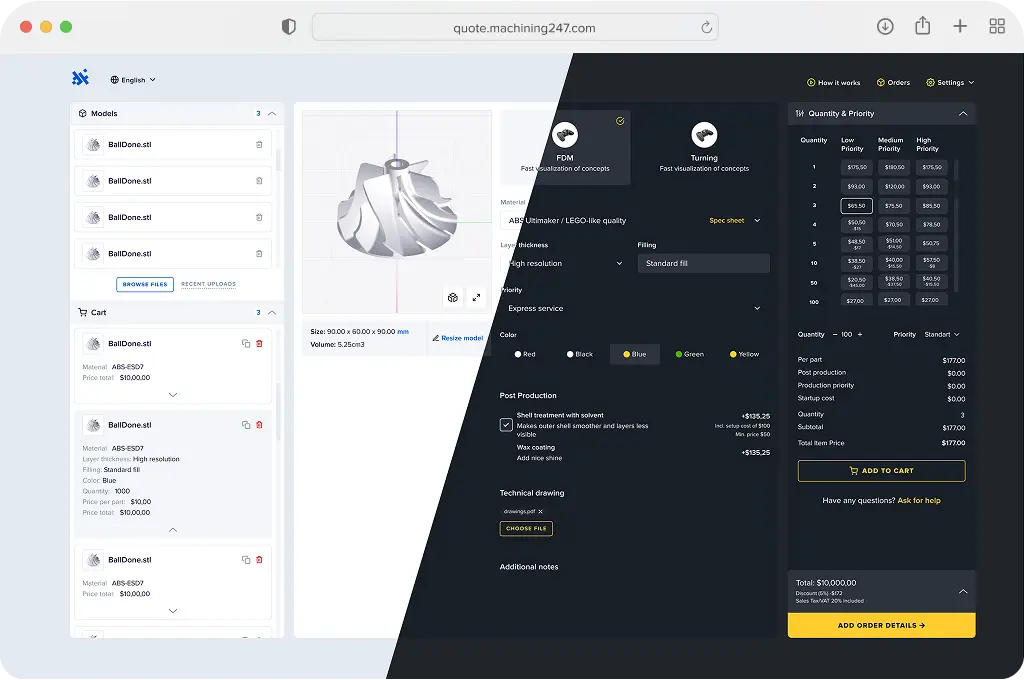

Get full control over your quotes with time-based precision and real-time cost breakdowns.

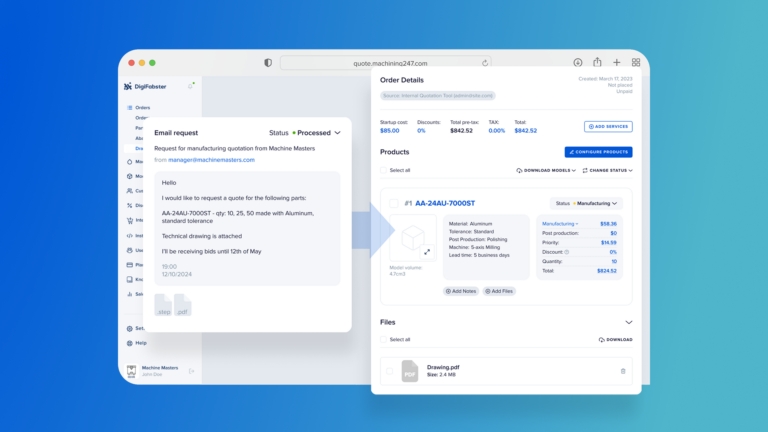

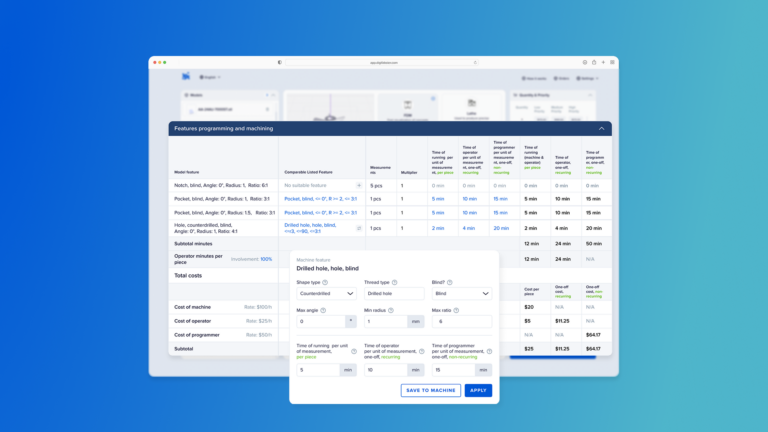

DigiFabster’s Quoting Copilot gives estimators, production managers, and shop owners a powerful way to analyze and adjust pricing in real time. This feature combines granular time-based costing, DFM insights, and machine-specific constraints — all in one transparent, editable interface.

Perfect for custom fabrication, CNC machining, metal shops, and any manufacturer who wants to see exactly what they’re quoting — and why.

🔧 What It Does

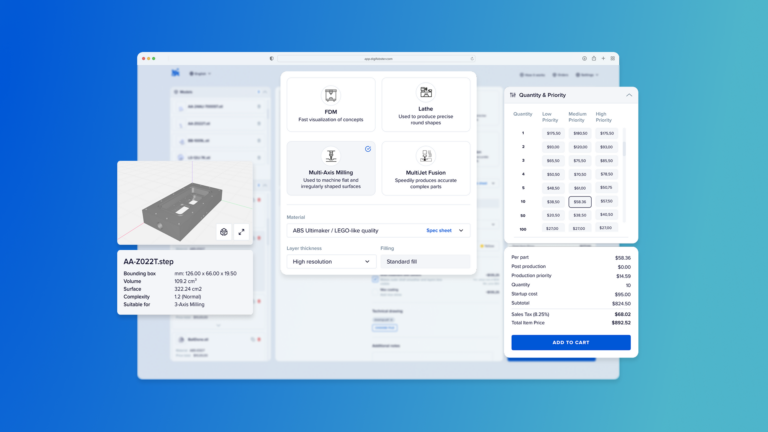

With Quoting Copilot, you can upload a CAD model and instantly:

- See the final quoted price along with every cost component that contributes to it

- Modify any operation time to adjust cost — and see pricing update in real-time

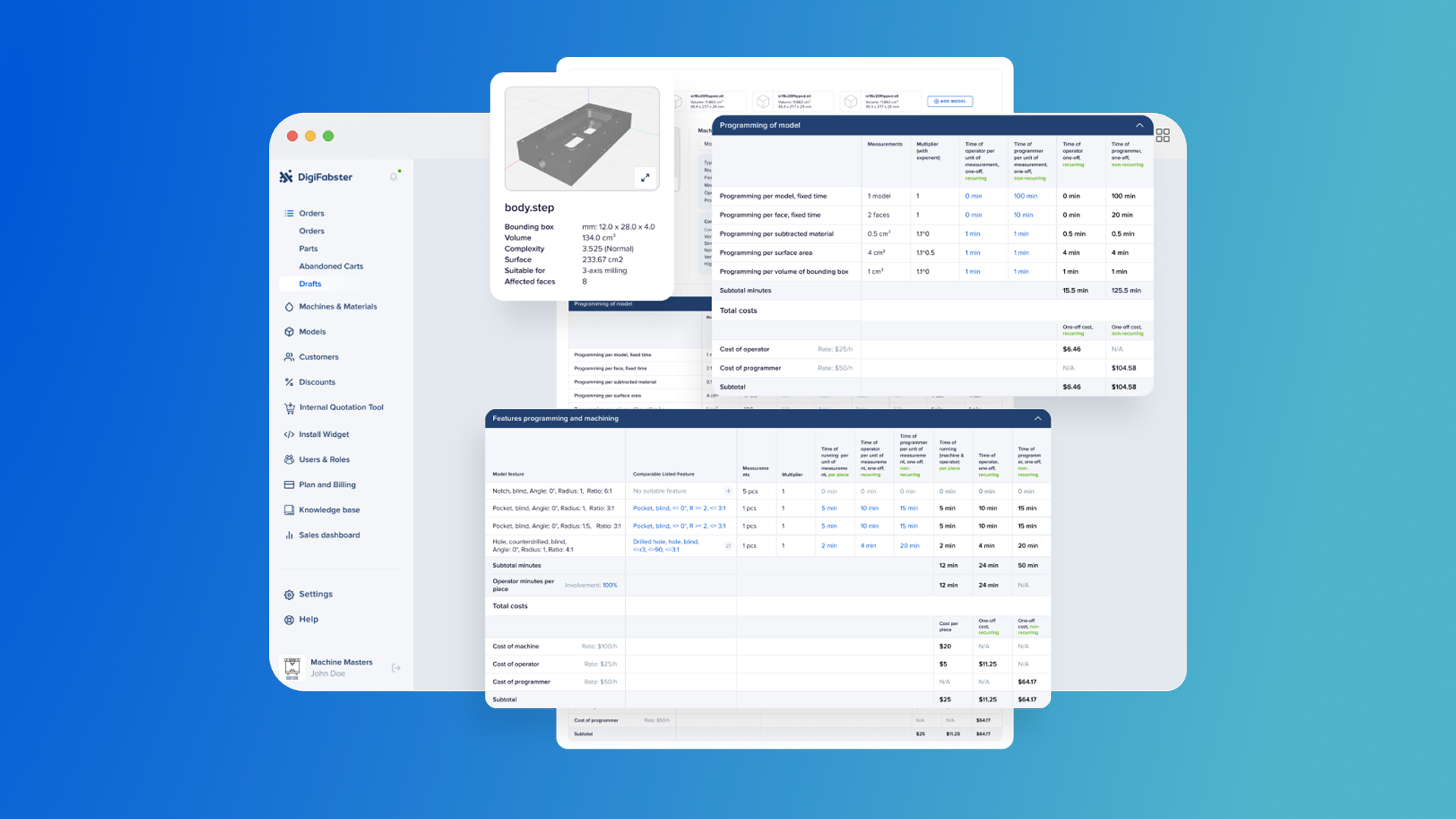

- Understand how the system calculated costs using a granular time-based model, leveraging: 🔹 Programming of Model

- Recurring and non-recurring programming time

- Cost can be calculated per part, per surface area, volume removed, or bounding box size

- Recurring and non-recurring time per feature (e.g. holes, pockets, threads)

- See which features are supported by the currently selected machine

- Time per clamp, cost of jigs, fixtures, or special tools

- Recurring/non-recurring setup time

- Cost per kg, based on part volume and selected material

- Time per bend and loading/unloading operations for sheet metal fabrication

- Time for roughing, finishing, or laser cutting, waterjet, plasma, etc.

- Adjust operator involvement with sliders to account for hands-on work, inspection, or fragile part handling

It’s a smart, flexible tool for improving cost estimation, job costing, and overall quoting confidence.

🏭 Problems This Solves

Problem: You don’t know where the price came from

✅ Solution: Copilot shows a full cost breakdown by operation — including programming, clamping, machining, material, and more.

Problem: Your team can’t fine-tune quotes easily

✅ Solution: Every time block is editable — from roughing time to jig setup. Adjust, approve, and quote with full clarity.

Problem: Generic pricing leads to missed margins

✅ Solution: Use machine-specific constraints and operation-based costs for smarter, more profitable quotes — especially in precision machining and prototype manufacturing.

🚀 How It Works

- Upload a CAD file into the quoting system

– The Copilot view appears automatically and breaks down the quote in real-time - Review detailed cost sections

– Each part of the process (e.g. programming, machining, clamping, material) is separated and editable - Tweak operation time and involvement

– Adjust time per feature, per bend, or per process; move sliders for operator attention as needed

💡 Pro Tip

Use Quoting Copilot when quoting high-precision jobs or unfamiliar part types. You’ll see instantly what’s driving the cost — and can spot where to optimize or upsell. It’s the perfect tool for estimators, sales engineers, and shops quoting a mix of one-off parts, metal components, or multi-step jobs.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.