Automatically fix broken models — no more quote delays or manual cleanup.

DigiFabster’s CAD Repairing engine is built to handle real-world files at scale. With over 100,000 models processed annually, we’ve trained our system to detect and correct the most common issues that stall quoting and production. From non-manifold edges to wall thickness errors, the system automatically fixes problems — helping your shop quote faster and with confidence.

Ideal for CNC shops, fabrication companies, 3D printing services, and on-demand manufacturers dealing with models from clients who aren’t always engineers.

🔧 What It Does

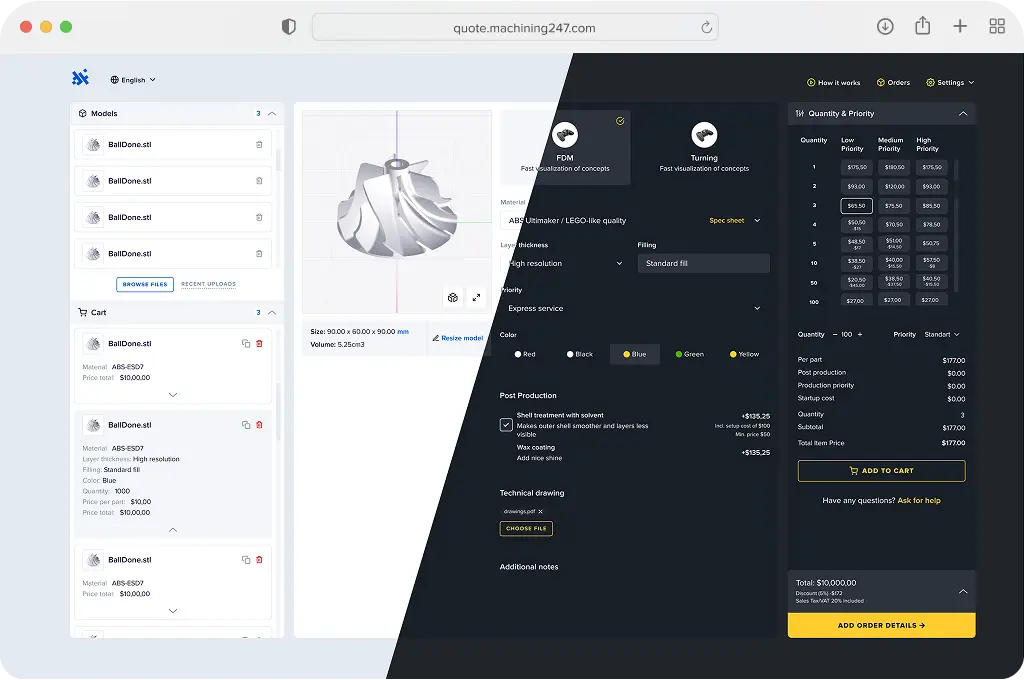

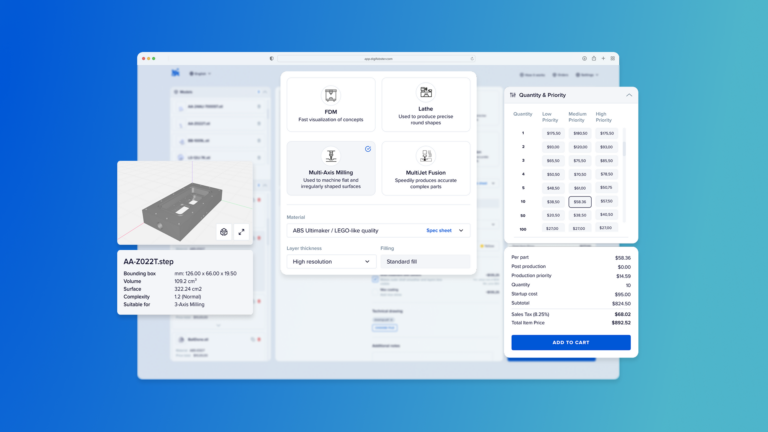

When a customer uploads a CAD file through your quoting widget, DigiFabster automatically:

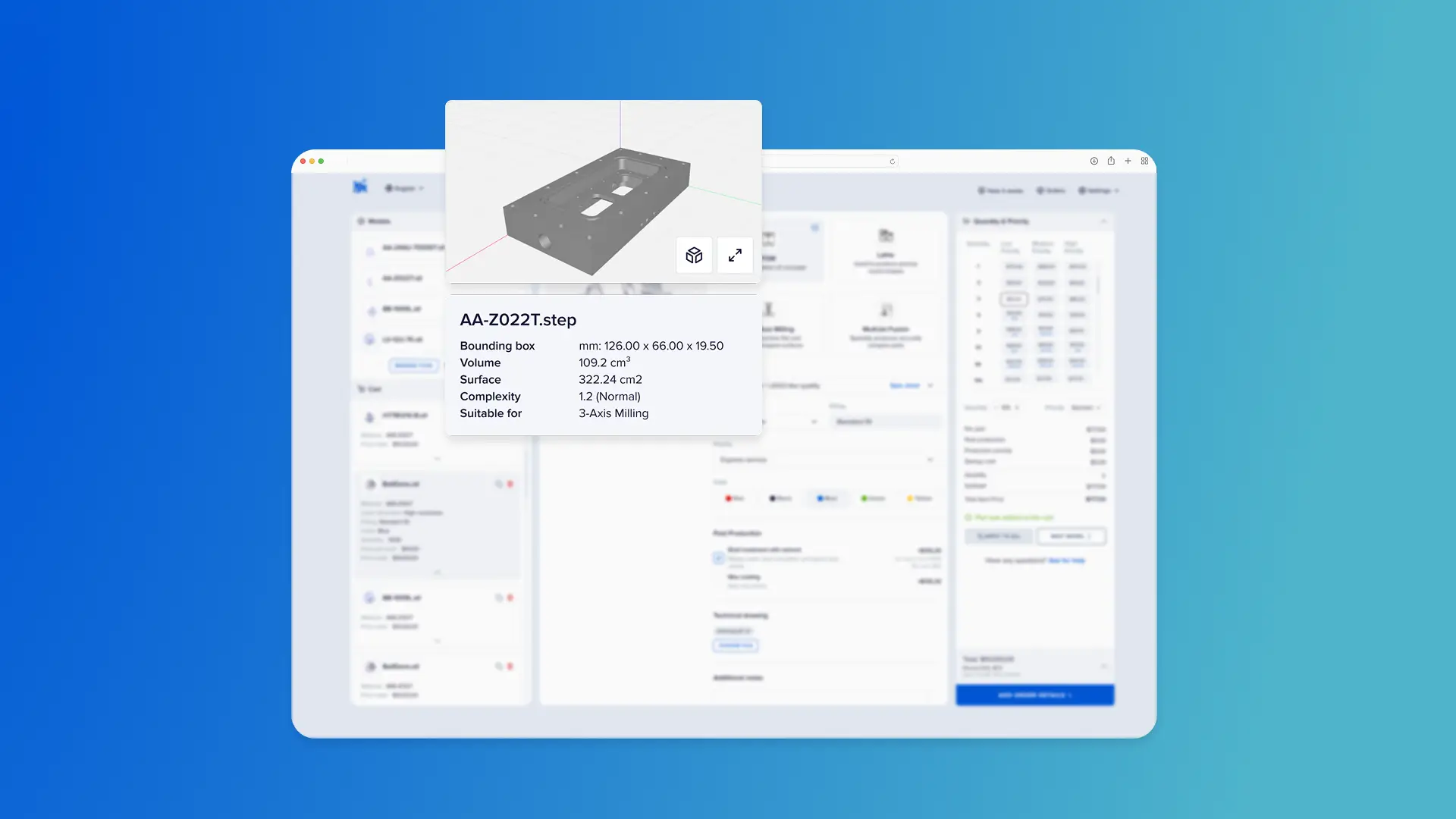

- Detects and repairs:

- Non-manifold edges

- Mispositioned triangles

- Unaligned or broken edges

- Unwanted gaps, holes, and surface openings

- Wall thickness issues

- Automatically adjust orientations, and fix errors to ensure perfect fit and manufacturability, streamlining the production process.

Whether you’re quoting for sheet metal, injection molding, metal fabrication, or 3D printing (SLS, MJF, SLA, SLM) — a clean model means a faster quote and a smoother workflow.

🏭 Problems This Solves

Problem: Broken or incomplete CAD files delay quoting

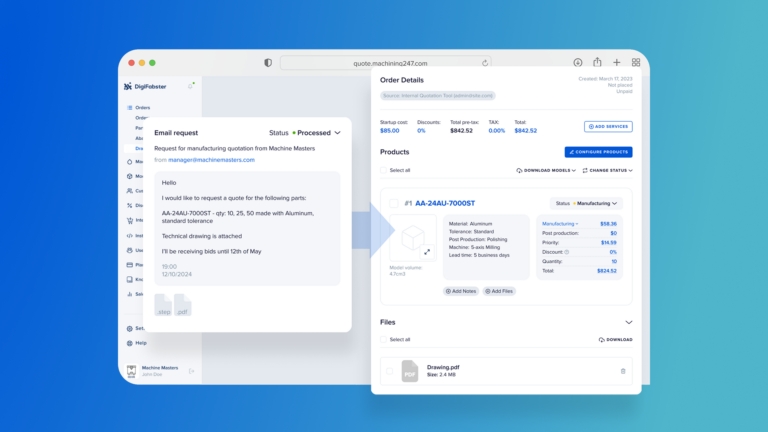

✅ Solution: DigiFabster repairs files instantly — so you don’t waste hours fixing geometry or rejecting jobs.

Problem: Customers don’t know how to fix model errors

✅ Solution: The repair happens invisibly. No need to educate customers or send files back — just quote and go.

🚀 How It Works

- It works out of the box

– No setup needed — model repairs are handled automatically on file upload - Customer uploads a CAD file

– Supported formats: STEP, STL, IGS, 3MF, DXF, etc. - DigiFabster scans and repairs the file

– All errors are fixed in real time so the part can be quoted and reviewed immediately

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.