Make it easy for your customers to configure and order parts — without a single email.

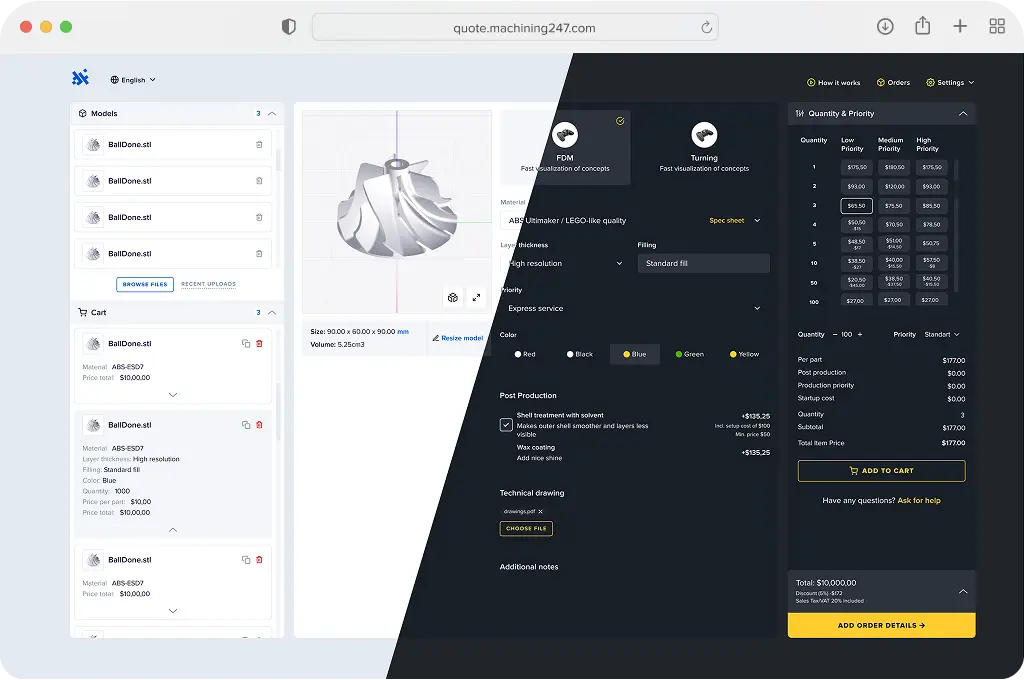

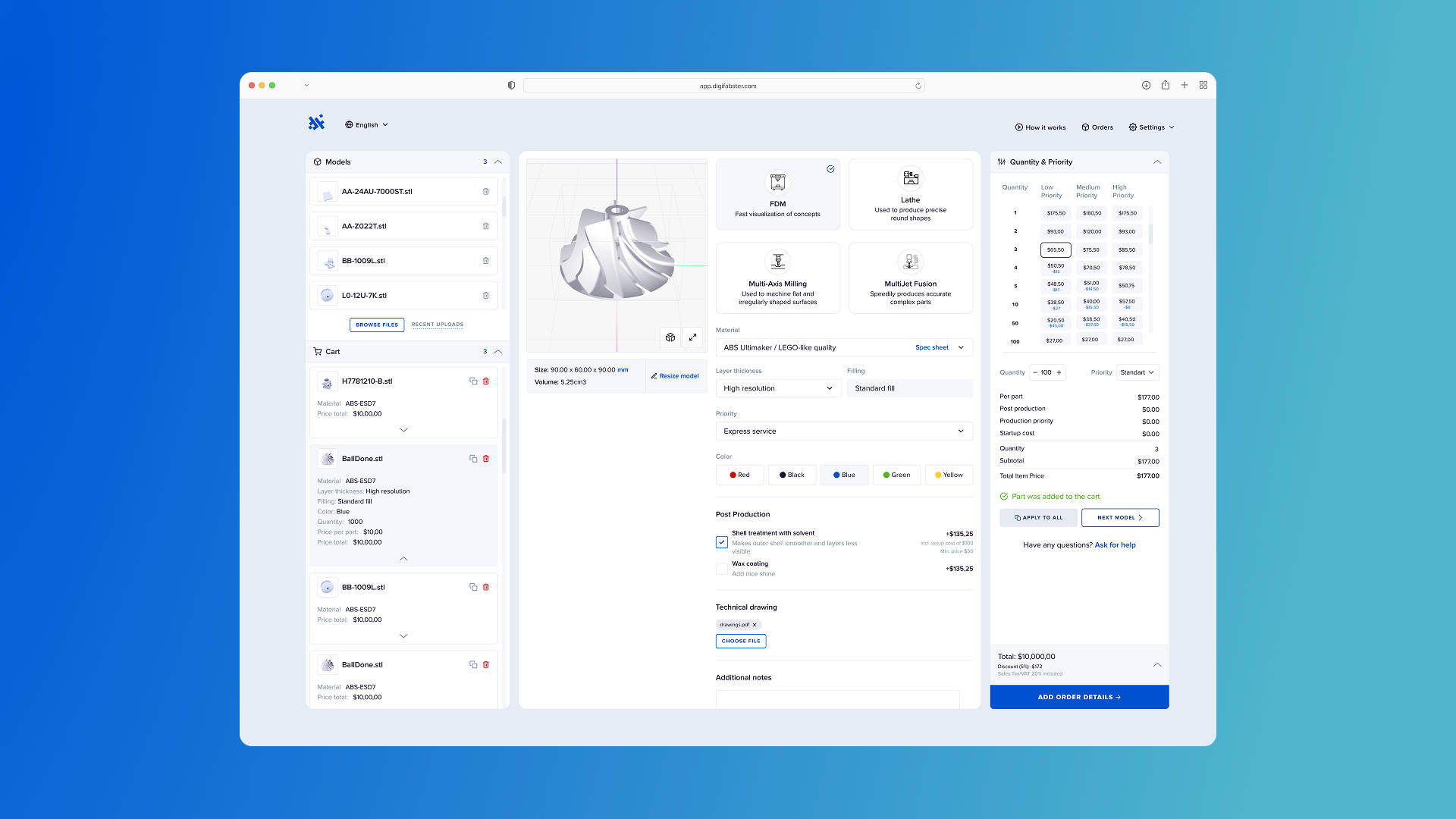

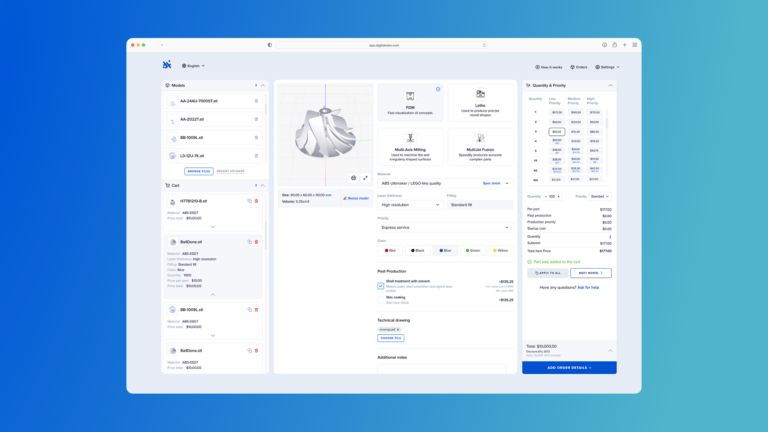

DigiFabster’s Online Storefront gives your customers an intuitive, e-commerce-style interface where they can fully define their parts before placing an order. From material selection to post-processing, colors, and tolerances, the entire process is streamlined for speed and simplicity.

Ideal for CNC machining, 3D printing, sheet metal fabrication, and custom manufacturing workflows — this feature enhances customer satisfaction and reduces quoting errors.

🔧 What It Does

After uploading a CAD file, your customer can:

- Select:

- Material type (aluminum, steel, plastics, etc.)

- Manufacturing process (e.g. CNC milling, laser cutting, 3D printing, injection molding)

- Post-processing options (anodizing, polishing, heat treating, etc.)

- Colors (if supported)

- Surface finish and tolerances

- Quantity and delivery preferences

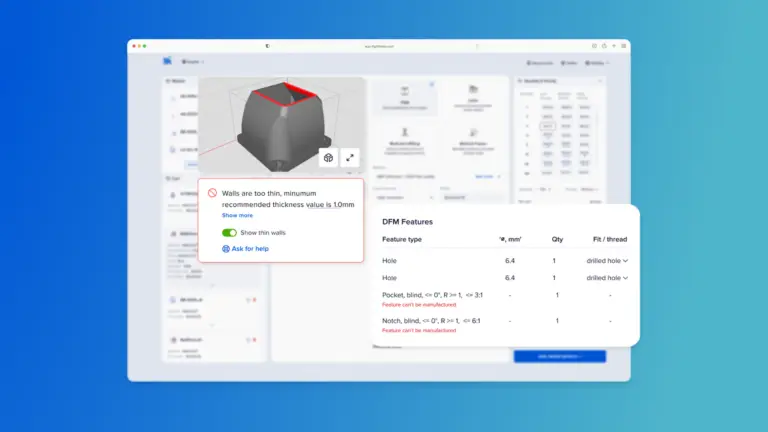

- Automatically detect part features and run DFM (Design for Manufacturability) checks:

- Analyze geometry in real time

- Assess manufacturability based on selected materials and processes

- Identify potential design issues like:

- Thin or unsupported walls (via wall thickness checks)

- Non-manufacturable features

- Overly complex geometry

- Ensure accurate pricing and reduce risk of production errors

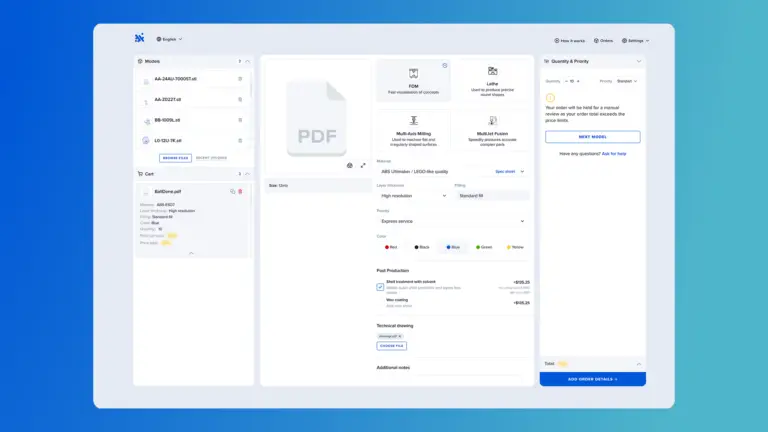

- See instant price updates based on selections (when pricing is automated)

- Submit orders confidently, with clearly displayed specs and visual feedback via the 3D CAD File Viewer

This reduces friction in the manufacturing workflow, builds customer trust, and increases quote-to-order conversion rates.

🏭 Problems This Solves

Problem: Customers don’t know how to submit complete RFQs

✅ Solution: A clean, step-by-step configurator guides them through everything — from model upload to final quote.

Problem: Sales teams spend time clarifying incomplete quote requests

✅ Solution: Orders come in with all specs defined — no more chasing material type, color, or tolerance data.

Problem: Quoted parts aren’t always manufacturable

✅ Solution: Built-in DFM checks, including wall thickness validation, ensure designs match your shop’s real capabilities.

Problem: Online ordering feels clunky or outdated

✅ Solution: This modern, e-commerce-style interface improves the buying experience, especially for repeat customers or tech-savvy buyers.

🚀 How It Works

- It works out of the box

– Configuration is integrated directly into your quoting widget or secure standalone solution - Customer uploads a CAD file

– Immediately enters the part configurator interface - They select all options step-by-step

– Material, process, post-processing, color, tolerances, quantity, and more - DFM runs automatically

– Flags manufacturability issues like thin walls, unsupported features, or oversize geometry - Order is submitted with full specs attached

– You receive accurate, optimized job data

💡 Pro Tip

Use DFM flags and wall thickness thresholds to trigger manual review mode for parts that need special attention — ideal for jobs involving 3D printing, metal bending, or fine tolerance machining.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.