Every manufacturing shop reaches a point where growth hits a wall — and more often than not, it’s not because of machines or materials, but because of process chaos.

Scattered files, inconsistent pricing logic, and tribal knowledge buried in one estimator’s head can grind operations to a halt. And when you’re quoting parts for sheet metal, multi-axis CNC machining, or 3D printing, even a small disconnect can cost you the job.

1. The Hidden Cost of File Chaos

Let’s face it — most fabrication shops and machine shops don’t have a real system for managing incoming design files. One day it’s STEP files, the next it’s STL with a separate technical drawing buried in an email thread. You save files manually to folders like “RFQ_John_2024”, only to realize you quoted that part last month — but with a different price.

Sound familiar?

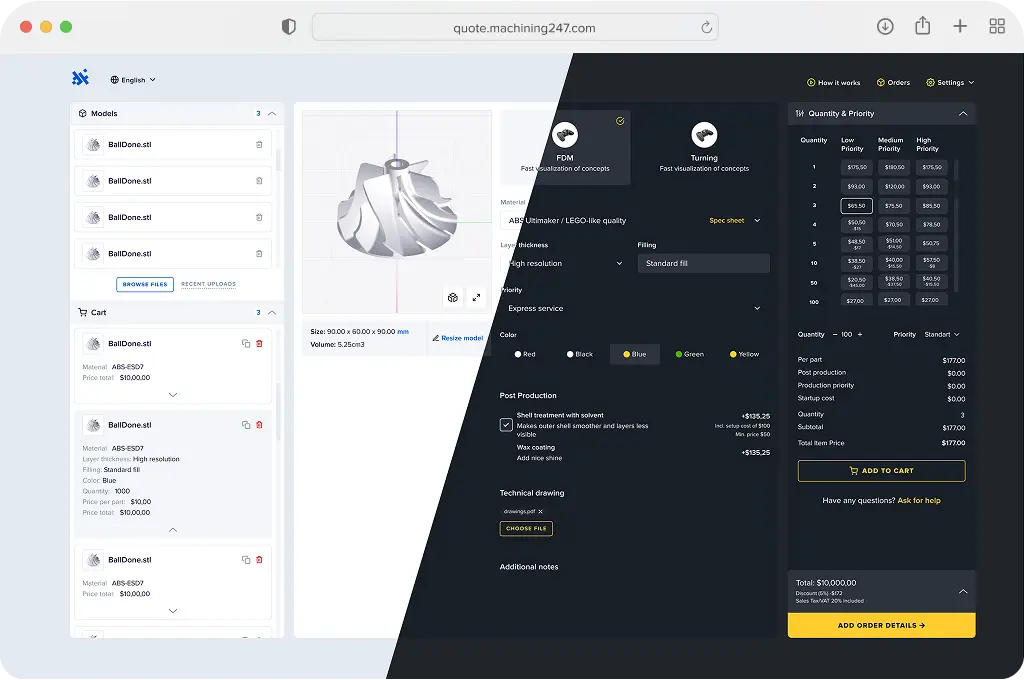

Digifabster’s Models Library feature brings order to that chaos. Every uploaded part — whether for sheet metal fabrication, 3D printing, or 5-axis milling — is automatically stored, organized, and searchable. You get:

- A visual, centralized library of all parts ever quoted

- Easy to use search and filtering

- Instant access to previous quotes and customers

- No more duplicated efforts or missing context

It’s like turning your chaotic inbox and desktop folders into a streamlined, searchable manufacturing database — one that works across your entire team.

2. Pricing Flexibility Without Losing Control

Another common pain for growing shops? Inconsistent pricing logic. Some estimators use one formula in Excel, others use gut feeling. You try to test a new pricing strategy for preferred customers — but changing the master spreadsheet could throw off the rest of your quoting flow.

Digifabster’s Internal & Exclusive Machines feature solves this in a way that’s elegant and scalable.

You can:

- Set up internal machines with specific cost estimation rules

- Assign them to certain customers

- Run private pricing strategies for loyal clients or strategic accounts

- Keep your overall pricing structure intact — no risk to standard workflows

This means you can experiment with discounts, premium lead times, or bulk pricing logic safely, without disrupting your quoting process for everyone else.

Perfect for contract manufacturers, custom fabrication services, and on-demand manufacturers working across multiple sectors or customer tiers.

3. From Reactive to Scalable

When file chaos meets pricing confusion, quoting becomes reactive — slow, risky, and frustrating. You chase RFQs, repeat work, and rely on memory instead of systems.

Systematizing your quoting process means:

- Centralizing your part data

- Automating your cost calculations

- Controlling access to special pricing engines

- Standardizing your manufacturing workflow

Digifabster helps you move from disorganized spreadsheets and siloed logic to a clean, modern CPQ workflow — one that fits job shops, metal fabrication companies, and high-mix, low-volume environments.

Final Thoughts

Growth starts with control. When you eliminate chaos in files and bring consistency to pricing, you unlock the ability to quote faster, win more jobs, and serve customers with confidence.

If your machine shop, fabrication business, or 3D printing service is ready to scale — it starts with a system.

Ready for the switch?

Learn more about Digifabster’s instant quoting, order management, invoicing, and payment solution here.

YOUR PATH FORWARD STARTS TODAY

Start your free trial now. No sales call required.