We are hiring. Join our team today!

DigiFabster Helps General Pattern Turn Orders in 2 Days or Less, Satisfying Customer Demand For Additive Manufacturing

90-Year old General Pattern develops new profit center with the help of HP’s Multi Jet Fusion 3D printing technology and software from DigiFabsterIntro

"We pride ourselves on our customer-centric approach. It’s a big reason why we’ve remained in business for over 90 years. We have a thorough understanding of each client and the industry they serve. They tell us about their challenges and we provide innovative solutions, transforming them into opportunities"

"We pride ourselves on our customer-centric approach. It’s a big reason why we’ve remained in business for over 90 years. We have a thorough understanding of each client and the industry they serve. They tell us about their challenges and we provide innovative solutions, transforming them into opportunities"General Pattern is a prototype, tooling and rapid manufacturing company with dedicated painting, decorating and assembly operations. The firm is headquartered in Blaine, Minnesota and was founded in 1922.

The company began by working for toy companies like Tonka, Hasbro, Mattel and others. When that industry shifted, General Pattern changed its focus towards the automotive industry. The company opened locations in Michigan and elsewhere and began making automotive parts. When business in that industry became unstable, General Pattern again changed its strategy.

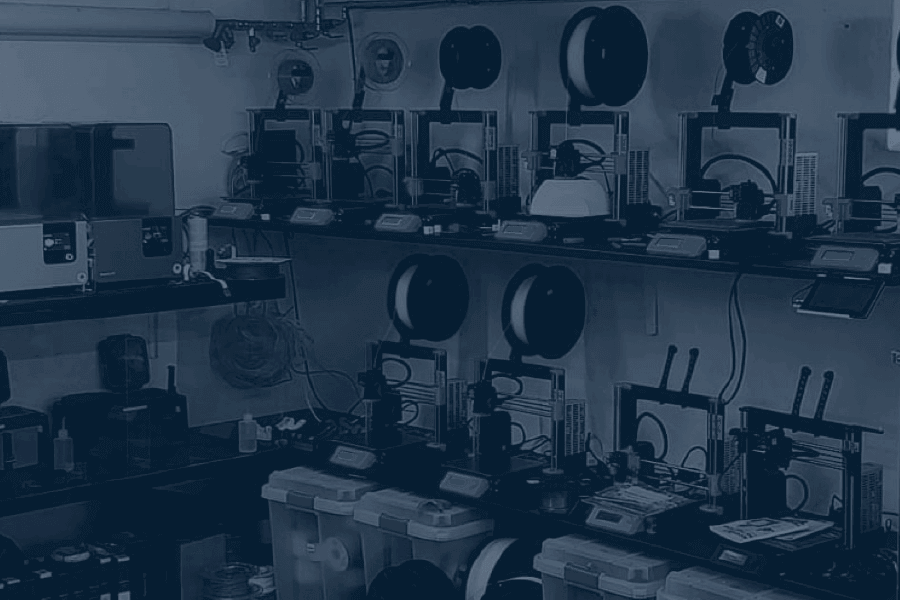

Presently, General Pattern provides services for a wide range of clients in many diverse markets. They have over 150 employees, operate out of twelve facilities and offer a wide range of capabilities including CNC milling, injection molding, thermoforming, foam molding and more.

Prototyping and Rapid Manufacturing

Automate front-end workflow to remove bottlenecks, allowing the company to provide pricing instantly and turn work more quickly

Seek out and implement a world-class software solution that would allow General Pattern to operate more efficiently and profitably, while simultaneously satisfying the needs of its most demanding customers

Challenge

"We’ve been intrigued with additive manufacturing for a long time. But until recently the quality, speed and capabilities just weren’t there. That all changed when HP introduced Multi Jet Fusion. Our customer was convinced it could help improve their products, both in the prototyping phase and in actual production. As their business partner, we were prepared and eager to meet the demand. But one of the byproducts of digital technology is that you end up with a lot of smaller quotes and orders. To be effective you have to automate"

"We’ve been intrigued with additive manufacturing for a long time. But until recently the quality, speed and capabilities just weren’t there. That all changed when HP introduced Multi Jet Fusion. Our customer was convinced it could help improve their products, both in the prototyping phase and in actual production. As their business partner, we were prepared and eager to meet the demand. But one of the byproducts of digital technology is that you end up with a lot of smaller quotes and orders. To be effective you have to automate"One of General Pattern’s clients, a well known name in the consumer products industry, needed a better, faster and cheaper way to make prototypes and end-use parts than could be accomplished with traditional manufacturing methods. After some conversation and testing, General Pattern decided to invest in HP’s Multi Jet Fusion (MJF) 3D printing technology. Their customer responded by flooding them with orders. As a result, the company began looking for a better way to manage front end processes like quoting and order entry.

General Pattern reviewed several different software packages. They wanted one that focused on ease-of-use, which would simplify the process for their client while also minimizing the amount of training for their staff. Further, they needed a vendor who was familiar with the nuances of HP’s technology, allowing them to develop pricing models that were as accurate and competitive as possible.

Solution

"Ease of doing business is one of the big reasons companies choose to work with General Pattern. We needed a software solution that embodied that. Further, we wanted a partner who had a thorough understanding of HP’s technology and could help us quickly implement their tool set. DigiFabster was the obvious choice"

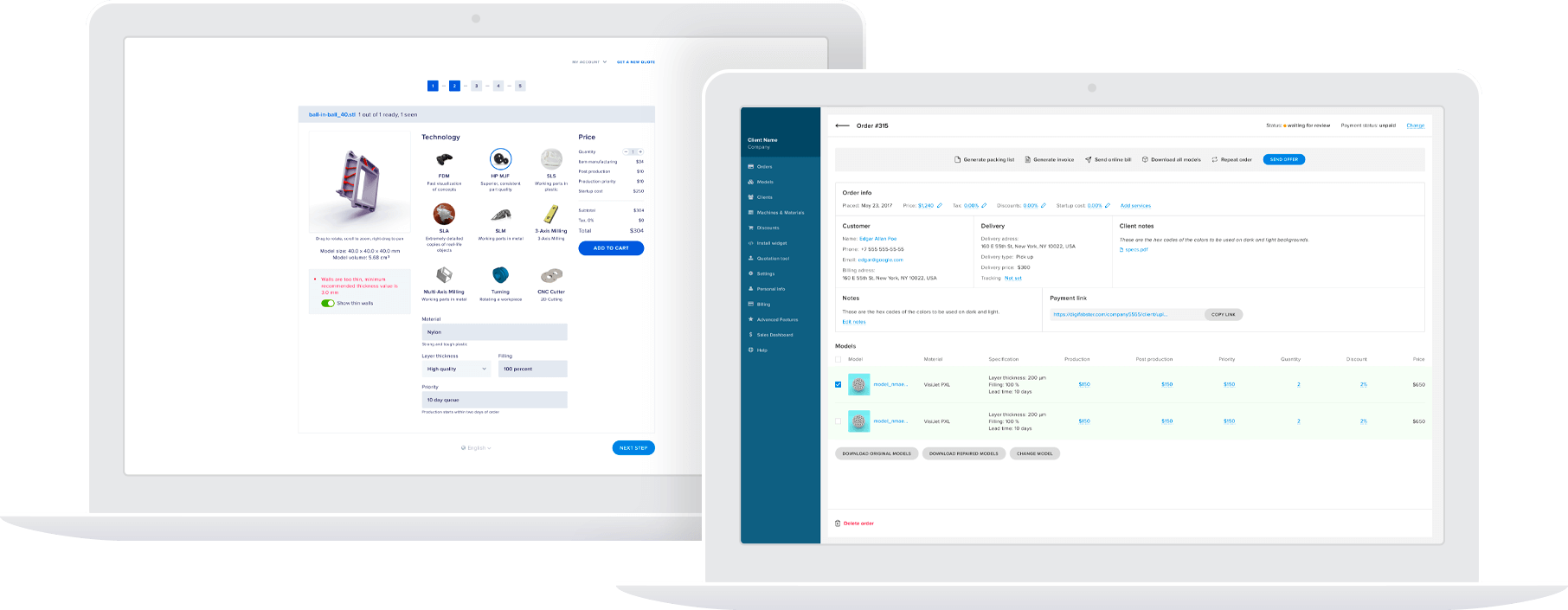

"Ease of doing business is one of the big reasons companies choose to work with General Pattern. We needed a software solution that embodied that. Further, we wanted a partner who had a thorough understanding of HP’s technology and could help us quickly implement their tool set. DigiFabster was the obvious choice"General Pattern started by reviewing a demonstration of the DigiFabster system. They wanted a solution that would allow them to quickly create a dedicated intranet page for one specific client. In the demo, they saw firsthand how easy it was to configure pricing and deploy an iFrame widget into any web page, whether it was public or private.

Further, General Pattern learned that DigiFabster had worked with many customers who utilize HP’s technology. The staff at DigiFabster also offered significant insight regarding best practices. In testing, they found that DigiFabster’s software could closely mimic their own offline pricing models in nearly any scenario.

As a result of DigiFabster’s software-as-a-service (SaaS) business model, General Pattern was able to quickly invest and implement a new online quoting and order entry software solution. They configured it based on their specific needs and communicated their new capability to their customer.

Result

"Our client was thrilled that we were able to find a solution that met all of their needs so quickly. DigiFabster’s front-end tool required very little training and they were able to start sending quotes and orders almost immediately. From our standpoint, it also helps us deliver final product much more quickly. We have everything we need without the back-and-forth that goes with email and phone calls. In many cases we’re now turning orders in 2 days or less!"

"Our client was thrilled that we were able to find a solution that met all of their needs so quickly. DigiFabster’s front-end tool required very little training and they were able to start sending quotes and orders almost immediately. From our standpoint, it also helps us deliver final product much more quickly. We have everything we need without the back-and-forth that goes with email and phone calls. In many cases we’re now turning orders in 2 days or less!"With DigiFabster’s instant quotation tool, General Pattern’s customer can upload their files, enter the specifications and receive a quote in real-time. If they are satisfied with the price they can immediately place an order. To eliminate mistakes and simplify production, the system also automatically checks and repairs any issues with each file before it is manufactured.

On the back-end, DigiFabster’s software provides the team at General Pattern with a detailed dashboard that displays each order and helps them manage tight deadlines. Further, the system also includes a customer relationship management (CRM) suite that automatically updates the client regarding job status.

“In today’s world we’re not just competing against other local shops,” says Ms. Thill. “Our industry has finally begun to embrace eCommerce technology. We’re excited to be one of the leaders in that space. Not only does DigiFabster help us reduce turn times and improve workflow, it helps us lock down our clients. They can go online and still work with a partner they know and trust.”

As the relationship between General Pattern and DigiFabster continues to grow, they’re now beginning to explore other opportunities. Currently, the firm is looking at how DigiFabster’s software could affect its CNC milling operations. Beyond that they plan to investigate how front-end workflow software could impact their business in other areas. They already know that automation can improve customer satisfaction while improving the efficiency and profitability of their company. The next step is to see how it can help them drive new business and better compete on a global scale.

To learn more about General Pattern, we encourage you to visit their website.

Quick Quote

Learn more about how DigiFabster Quick Quote can help your 3D printing service bureau improve the customer experience, while reducing costs and generating more revenue