We are hiring. Join our team today!

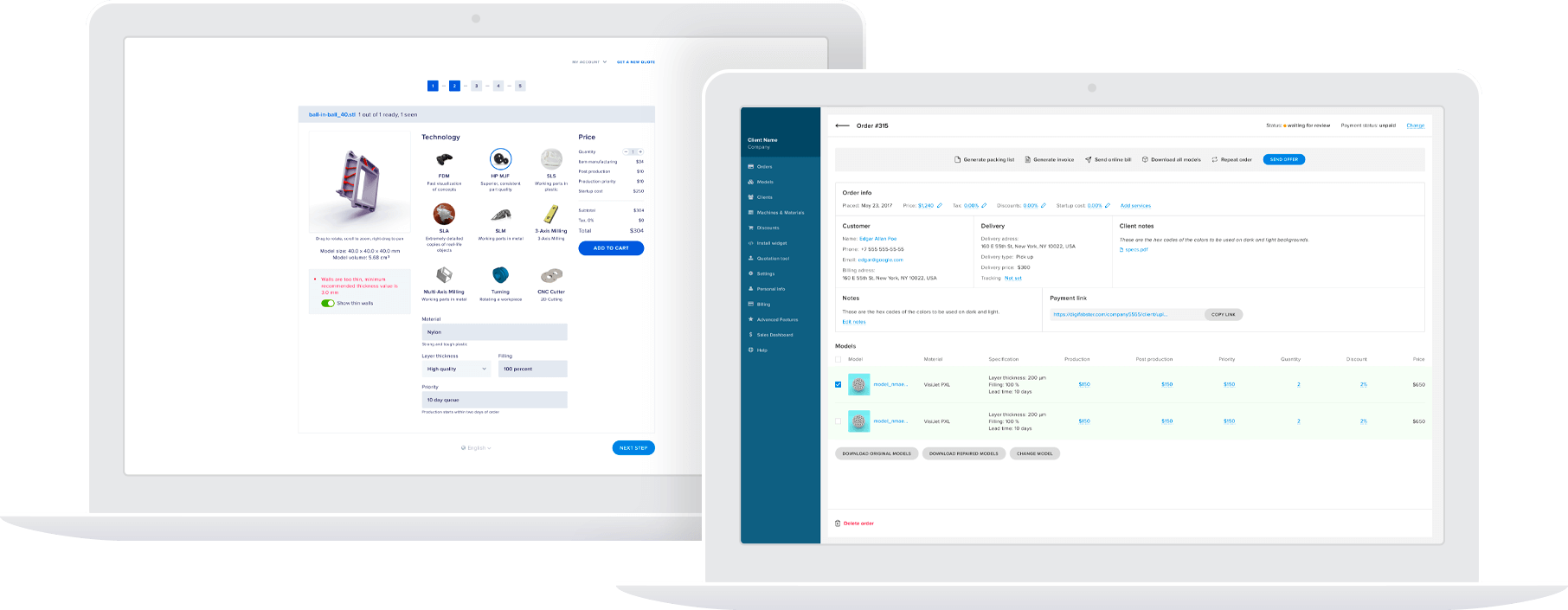

DigiFabster partners with leading German industrial plastics manufacturer to automate their CNC quotes

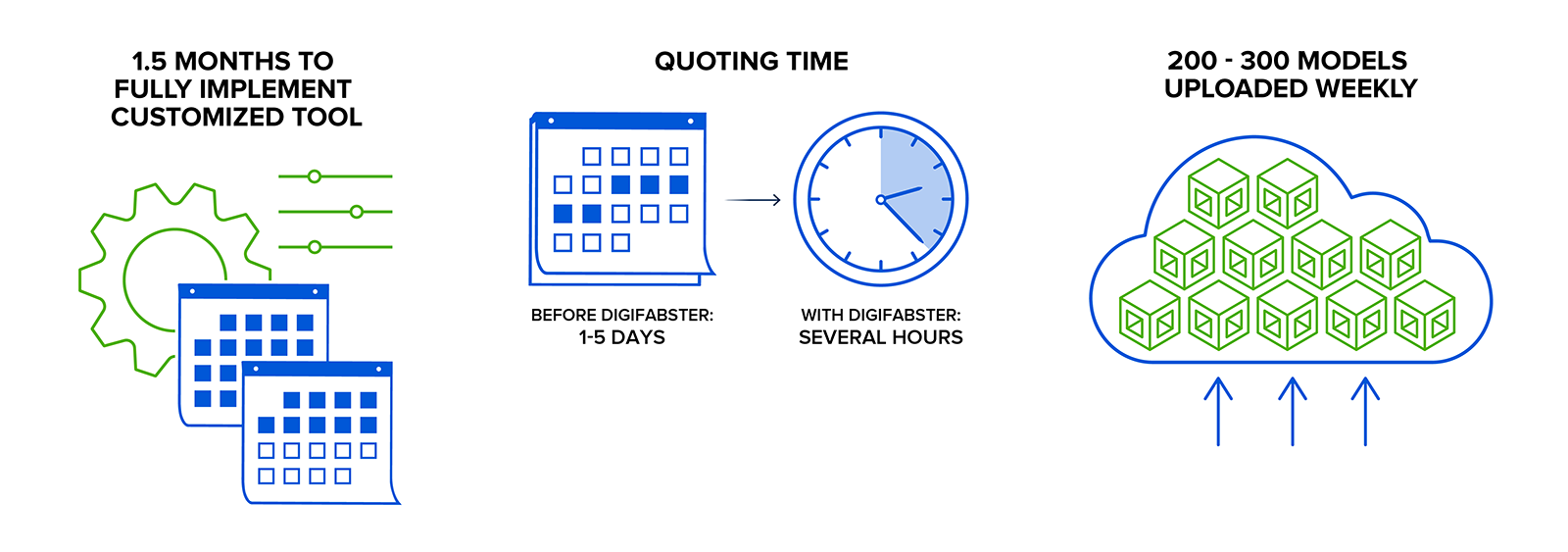

This leading industrial plastics innovator already had an in-house quote automation tool for their 3D printing business, but they needed a similar solution to grow their CNC machining business. Several hoursQuoting time

Several hoursQuoting time 1.5 monthsTime to fully implement customized tool

1.5 monthsTime to fully implement customized tool 200 - 300 weeklyUploaded models after implementation

200 - 300 weeklyUploaded models after implementationThis leading manufacturer of industrial low-friction plastics in Germany develops and produces applications such as bushings, bearings, parts and systems for linear or rotational movement and robot arms across nearly all industries: from automotive to public infrastructure.

Their manufacturing capabilities span 3D/AM, CNC machining and injection molding. Most of the firm’s customers use the 3D printing and CNC service for prototyping, then move to other services like injection molding for mass quantities.

3D/AM, CNC, Injection Molding

- Offer the same quick and accurate automated quoting service available to 3D/AM customers for CNC customers

- Leverage software partner to customize CNC automated quoting

- Work with DigiFabster to develop, implement, and iterate customer-facing quoting software

- Place thresholds on automated orders that may require an additional manual check

Challenge

While this firm already had an automated 3D quoting solution in place for their customers, they were still quoting CNC jobs manually, which took a significant amount of time. Especially when coordinating with certain suppliers, CNC quotes could take up to five days to be delivered to their customers.

To save time and labor costs, the firm’s lean engineer opted out of developing net-new CNC quoting software in-house, as they had for their 3D/AM business. Instead they searched for an automated quoting software partner who they could co-develop a tool with.

Luckily, in 2019 they found DigiFabster, and we had just started developing our CNC quoting tools. This led to collaborative partnership where DigiFabster could further develop, test, and improve our CNC tools with a heavy-hitting industry partner.

Since this was DigiFabster’s first CNC client, a development process preceded the implementation process, which included making sure data inputs like supplier prices were working properly, integrating the software into existing automated and manual processes within the company, and optimizing the pricing accuracy for more complex parts.

Once the development and QA process concluded, it took less than two months for the DigiFabster quick-quote tool to be fully implemented to the firm’s customer interface and backend operations. During this time, DigiFabster also worked with the firm on employee training and Q&A sessions.

Solution

Now, with DigiFabster fully implemented, the CNC calculations take mere minutes. Once the manual checks for feasibility are completed, the firm can get back to their CNC customers in a matter of hours instead of days.

DigiFabster’s tool uses an average price for suppliers that impacts margins to a degree. But overall, fast quoting is more important to the firm’s bottom line than consistently wide margins because they can process a higher volume of orders.

This required the company to shift its mindset away from getting objectively large margins on every single order toward aiming for satisfactory margins on a larger number of orders. (See our Overengineering series to see how this works in more detail.)

Since then, the firm relies on the software to process the majority of uploaded models and only turn to manual quoting for especially complex jobs.

Results

This firm chose to work with DigiFabster because we were able to create the tool quickly, process feedback and offer a fair price for the software as a service.

It’s been a year-and-a-half since we launched the CNC quoting tool with this firm and so far it’s allowed them to offer different delivery timeframes (standard vs. express), and create an internal process for expedited orders, which customers love.

Other positive results since implementing Digfabster include:

- Overall number of RFQs has increased

- 200-300 uploaded models per week

- 50% increase in outside inquiries using the DigiFabster tool during the current quarter

- Average quote time down from 1-5 days to 4-24 hours