We are hiring. Join our team today!

MakeItQuick Leverages DigiFabster to Reduce Quoting Costs by 95% and Order “Transaction Costs” by up to 85%

DigiFabster helps MakeItQuick reduce the cost of quotes and orders, allowing the company grow revenues by 25% per monthIntro

"We are a fast growing 3D printing service bureau serving a wide range of industries. Our clients range from start-ups to large, well-established companies and span many different markets from automotive and aerospace, to architecture, education and more."

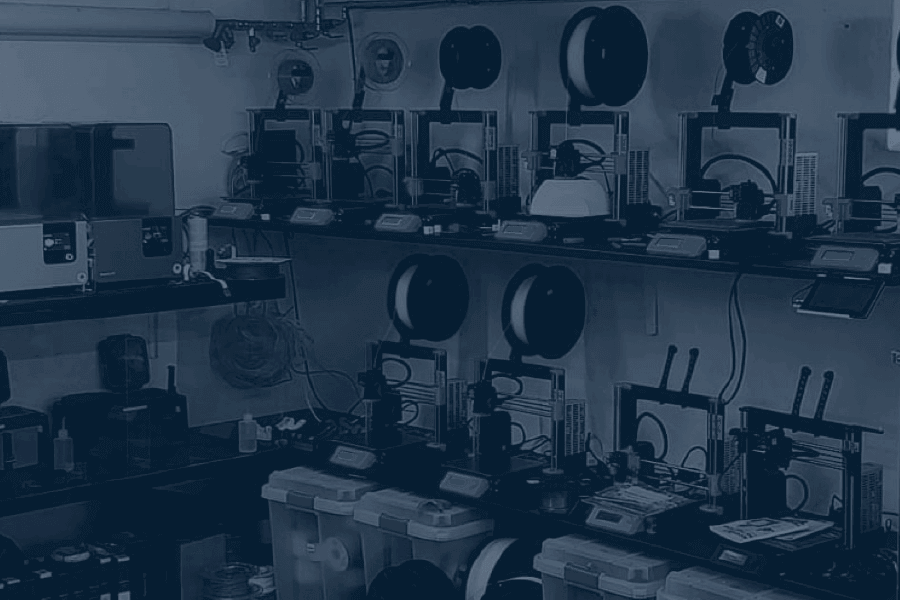

"We are a fast growing 3D printing service bureau serving a wide range of industries. Our clients range from start-ups to large, well-established companies and span many different markets from automotive and aerospace, to architecture, education and more."MakeItQuick is an additive manufacturing service bureau located in Newcastle upon Tyne, United Kingdom. The company offers a range of 3D printing services and many different types of plastics, including ABS, nylon and flexible polymers. In addition, MakeItQuick offers several post-processing capabilities from sanding and bead blasting, to painting and assembly.

“Our mission is to bring additive manufacturing to people,” says Mr. Massi. “The idea behind it is to make hiqh quality, digital manufacturing more affordable and readily available to private customers and businesses alike.”

MakeItQuick supports a large portion of the product development lifecycle - from prototyping to small batch manufacturing - and this full-service approach creates significant value for their customers.

Prototyping and Small-Batch Manufacturing

Automate front-end tasks like quoting and order management, saving the company money, while allowing it to scale more effectively

Identify and implement a best-of-breed solution that would allow MakeItQuick to quickly and easily implement web-based software, replacing manual business processes

Challenge

"In the first weeks of our business, we managed everything with phone calls, emails and clunky Excel spreadsheets. We needed an all-in-one, organized system that would allow us to manage clients, quotes, and orders, so we could focus on turning jobs and growing our business."

"In the first weeks of our business, we managed everything with phone calls, emails and clunky Excel spreadsheets. We needed an all-in-one, organized system that would allow us to manage clients, quotes, and orders, so we could focus on turning jobs and growing our business."Shortly after founding the business, the team at MakeItQuick recognized a crucial challenge for their business. If they were going to scale they needed to eliminate much of the redundant work that goes with managing quotes and orders.

They started by measuring the amount of time they were spending on manual tasks like quoting and order management. They found that each quote took anywhere from 10 minutes to more than an hour, and determined that the average cost per quote was £15.00 and that it cost £15-20.00 to push each order through its facility.

Solution

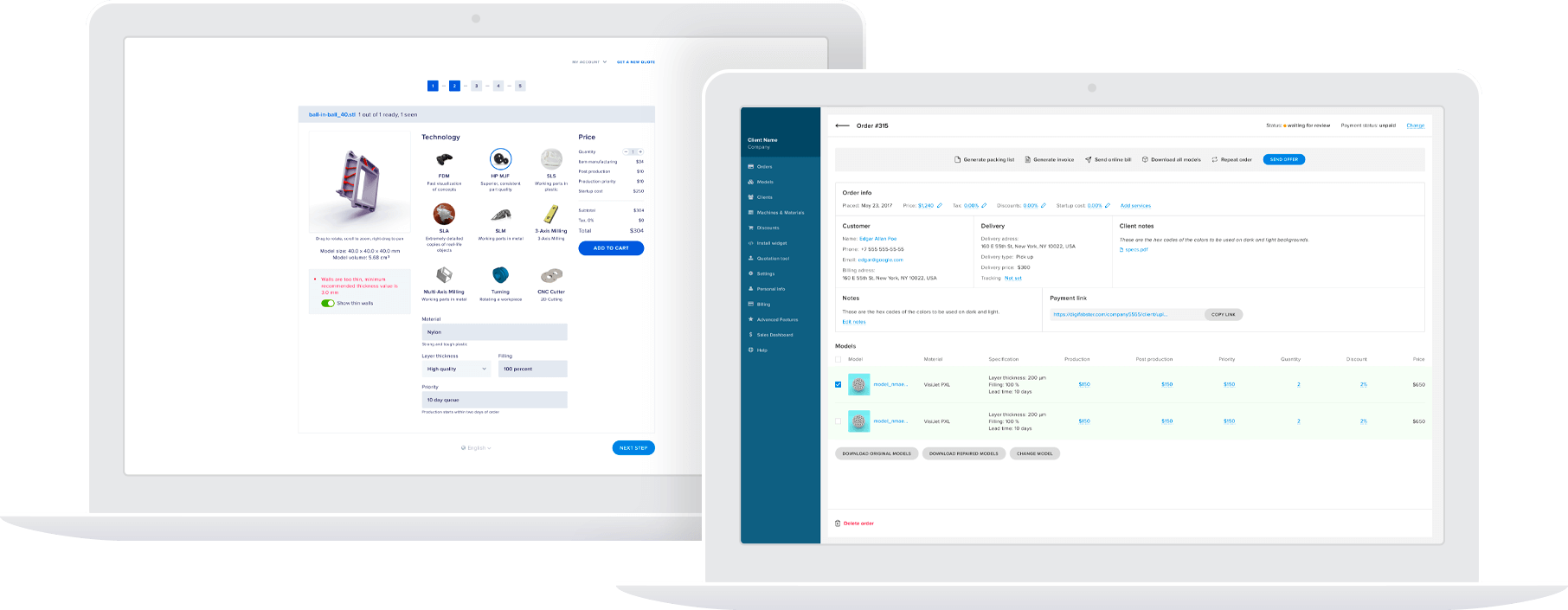

"DigiFabster is the go-to solution when it comes to quoting and CRM for 3D printing service bureaus. We adopted their software shortly after opening our business, and leveraged it to immediately automate much of the redundant, front-end work in our shop."

"DigiFabster is the go-to solution when it comes to quoting and CRM for 3D printing service bureaus. We adopted their software shortly after opening our business, and leveraged it to immediately automate much of the redundant, front-end work in our shop."MakeItQuick began by reviewing a demonstration of DigiFabster’s software. They needed a solution they could quickly configure and deploy on the company’s order page. In the demo they saw how easy it was to set up pricing and generate an iFrame widget, which they could embed directly on their company’s web site.

MakeItQuick signed up as a customer and began working with the software. In just a few hours they were able to get everything configured and implemented on their site.

Result

"The software handles 90% of our quotes without the need to manually review every part that is submitted. The time savings were immediately evident."

"The software handles 90% of our quotes without the need to manually review every part that is submitted. The time savings were immediately evident."Once the DigiFabster solution was up and operational, MakeItQuick began recalculating their cost-per-quote. They found that since the vast majority were automated, their costs were reduced down to a few pence, saving them as much as 95% per quote.

“We save even more once a quote is confirmed,” says Mr. Massi. “All the order details are at hand, giving us the opportunity to analyze the data and decide on the best way forward.”

The amount of time it took to manage an order and take it through the manufacturing process was greatly reduced. With DigiFabster, the cost dropped to just a couple of pounds per order, saving anywhere from £12-18.00 on each transaction.

For more on the costs of order management, check out our blog article: How Transaction Cost Can Hurt Your Manufacturing Business …and What to Do About it

“In less than a year with DigiFabster, our revenue has grown steadily,” says Mr. Massi. “We’re now experiencing a 25% monthly revenue increase, paving the way for our future success.”

All of the time savings have yielded big benefits for MakeItQuick. They’re able to serve more customers without expensive increases in labor. They’ve reinvested those savings back into higher value activities, which has lead to steady growth.

“As the owner and director here at MakeItQuick, my time is split between managing production and taking care of business development,” says Mr. Massi. “Less time spent managing orders means I can spend more time cultivating new business.”

With the automation of quoting, order entry and project management, MakeItQuick has proven its ability to scale and with DigiFabster’s unique software solution in place, MakeItQuick is delivering on its promise of “bringing additive manufacturing to people.

To learn more about MakeItQuick, we encourage you to visit their website.

Quick Quote

Learn more about how DigiFabster Quick Quote can help your 3D printing service bureau improve the customer experience, while reducing costs and generating more revenue