We are hiring. Join our team today!

In-house rapid prototyper at multi-billion dollar company leveraged DigiFabster for superior efficiency

Client Profile

Challenge

- Unruly and disorganized order management

- Inefficient submission process

- Unclear/inaccurate cost reporting to upper management

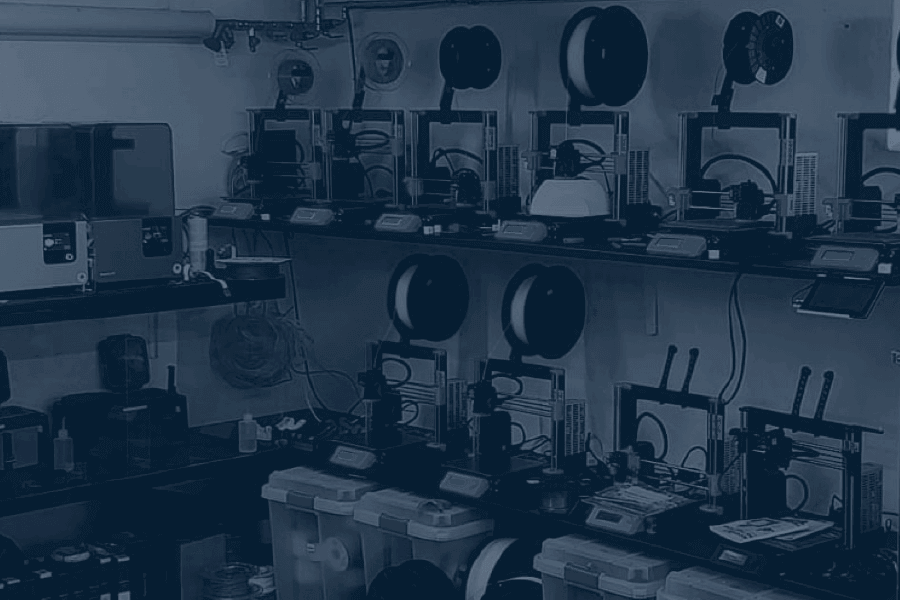

Our main client is the head of a rapid prototyping shop for a major division within a multinational designer and manufacturer of home improvement tools.

If you’re an average household virtually anywhere in the world, chances are you own at least one power tool, piece of lawn equipment, or floor care appliance that was designed, produced and marketed by this industry leader.

As an internal job shop, our client manages and executes requests from stakeholders across several brands. They produced 20,000 parts last year alone. If they were an independent shop, their annual revenue would be roughly equal to ~$900K.

However, they lacked a unified system to receive and manage orders or quote departments on costs.

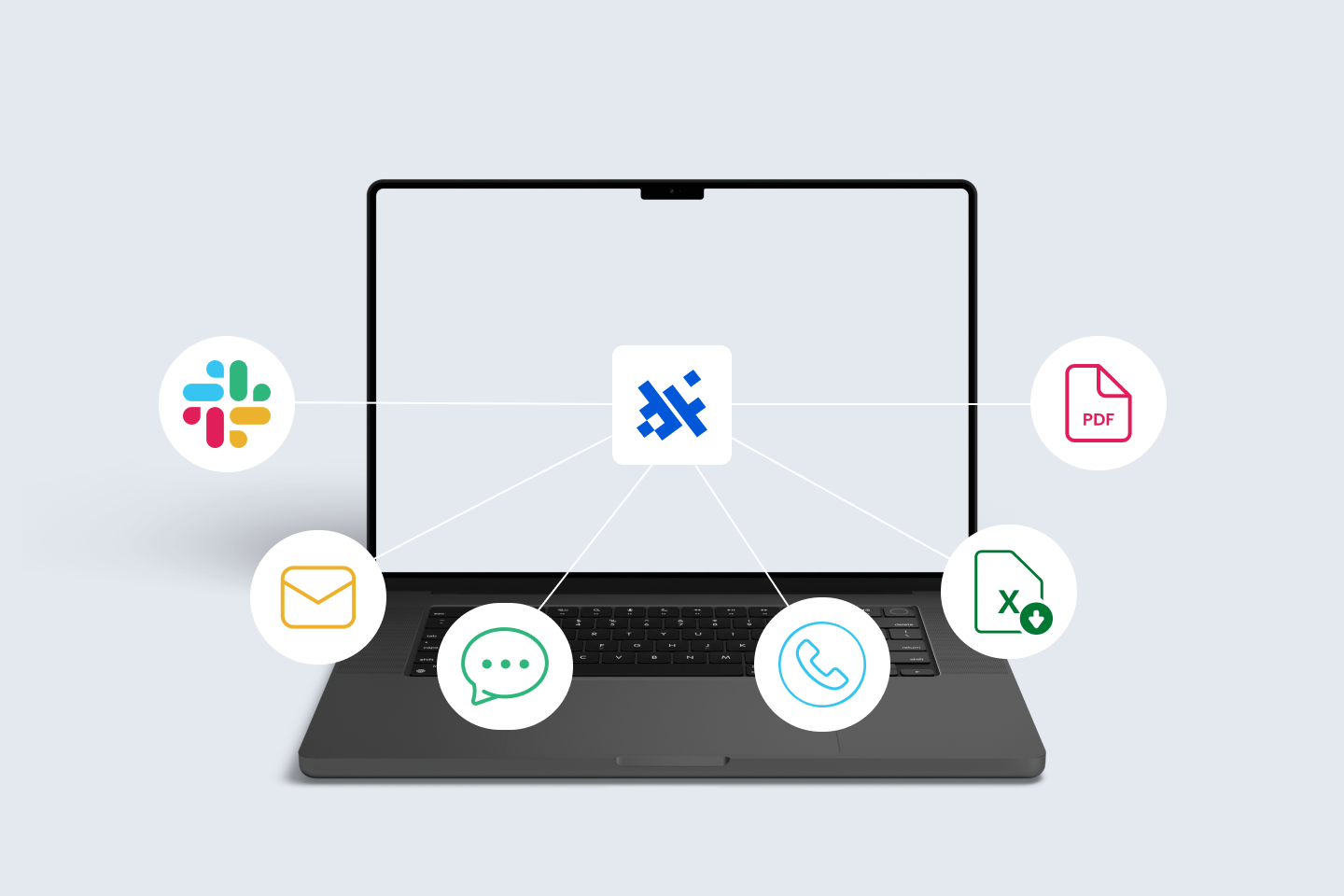

Quoting was manual, and communication was spread across various channels, the main one being emails back and forth between the shop and their requesting counterparts.

They needed a streamlined and automated approach for receiving and processing orders, generating quotes, and keeping track of costs.

“This is a problem I've seen in multiple shops. A request system is important — it's a big key that internal shops are missing."

Solution

"DigiFabster makes it easy to show upper management how we're saving money by keeping prototyping in house, and we can clearly illustrate a high ROI."

Rather than spend time and incur additional costs building out their own order interface, this shop leveraged DigiFabster’s ecommerce and instant quote functionality as an internal tool, servicing design and development departments across the entire floor care division with online “storefronts.”

The strategic solution

- Leverage DigiFabster’s ecommerce platform as a streamlined ordering system for internal stakeholders

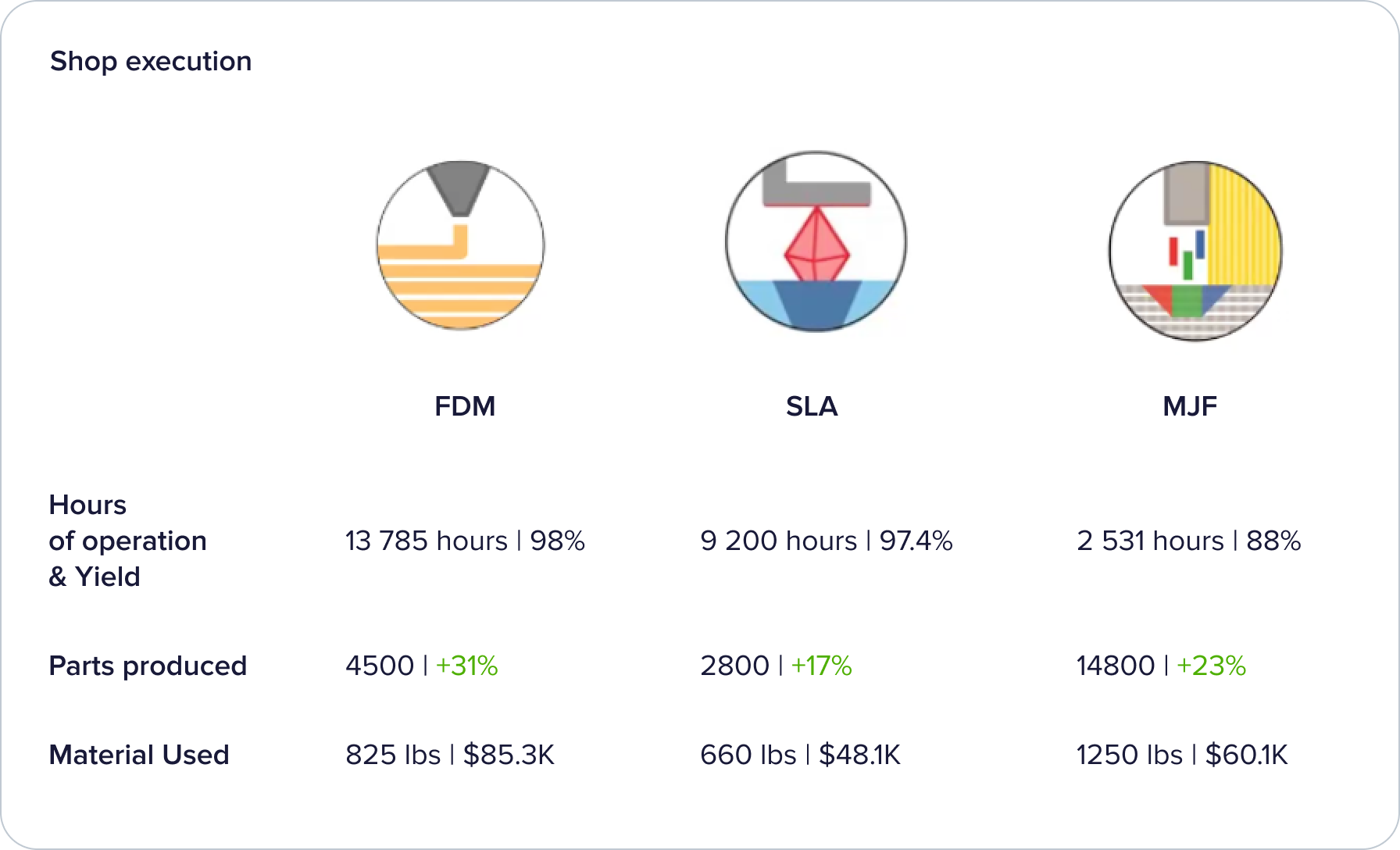

- Provide several “storefronts” as a self-service for stakeholders and various manufacturing technologies (FDM, SLA, MJF)

- Cut down communication time between shop and stakeholders by leveraging DigiFabster QuickQuote

- Allow stakeholders to track their requests and production status within the DigiFabster platform

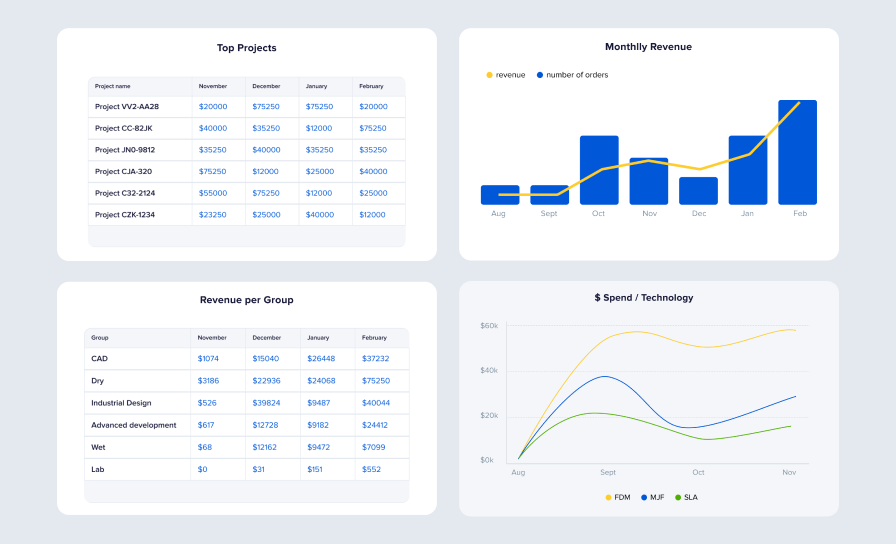

- Leverage estimates and order management data for reporting costs and productivity to upper management

The job shop used to report hours, costs, and weight of materials to demonstrate company expenditures.

Now they easily generate detailed reports with pure financials, categorized spends, ROI, and illustrate where company investments should be adjusted.

“Unifying our shop’s requests all in one place was the first priority, and the financials were a fast follow.”

Results

Centralized, streamlined and optimized for everyone

Through various “storefronts” for stakeholders that allow them place orders and see order status in real time, plus the ability to automatically place jobs directly into a technician’s queue and onto machines, this internal rapid prototyping shop has shrunk quote and communication time and supercharged their productivity.

Another added bonus of their digital transformation? Easy data management and accessibility. Previously, the shop’s reports to upper management were vague and couldn’t make a truly compelling case to keep rapid prototyping within the company’s vertical stack.

With DigiFabster, the shop can show upper management an accurate dollar value of keeping rapid prototyping in-house, rather than outsourcing to a third party.

The shop now generates detailed reports that upper management not only understands, but prefers.

Another happy client

Of upgrading his shop with DigiFabster’s solutions, our client is almost in disbelief.

“I still think it’s amazing,” he says. “This many parts being made with only 3 people. It couldn’t be done without an organized system on the front side and the technology of software-to-hardware to complete it.”

He also loves the easier budgeting DigiFabster has unlocked, as well as making a case for new equipment, and the inverse — recommending offloading underused machines. It’s all transparent and accessible with DigiFabster.

Our client has great things to say about the nature of our partnership. They’ve been able to make specific functionality requests and give us ideas for optimizing features, which DigiFabster has been happy to respond to. We’re driven by customer success, so an ongoing loop of feedback and iteration is core to our business.

“DigiFabster is a solid product and we’re glad we found you. If you told me about this 20 years ago, I wouldn’t believe it could be done.”

Quick Quote

Learn more about how DigiFabster Quick Quote can help your 3D printing service bureau improve the customer experience, while reducing costs and generating more revenue

This metal and plastic cutting shop serves a specific customer with the power of DigiFabster

DigiFabster Revolutionizes Quoting and Customer Experience for this Rapid Prototyping Service

DigiFabster Saved Up To $20.000 (USD) For Northern Layers On Web Development Costs